Investigating the Environmental Impact of Graphite Crucibles: A Comprehensive Analysis

Investigating the Environmental Impact of Graphite Crucibles

Graphite crucibles play a pivotal role in various industries, from metallurgy to electronics. As the demand for these crucial components continues to rise, understanding their environmental impact becomes increasingly important. In this extensive article, we will explore the different facets of graphite crucibles, examining their production processes, resource sourcing, and waste management practices. Additionally, we’ll highlight sustainable alternatives and future trends that could shape the industry.

Table of Contents

- 1. Introduction to Graphite Crucibles

- 2. The Production Process of Graphite Crucibles

- 3. Resource Sourcing: The Environmental Aspect

- 4. Applications of Graphite Crucibles

- 5. Waste Management Practices in the Graphite Industry

- 6. Sustainable Alternatives to Traditional Graphite Crucibles

- 7. Regulatory Framework Governing Graphite Production

- 8. Future Trends in Graphite Crucible Production and Environmental Impact

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Graphite Crucibles

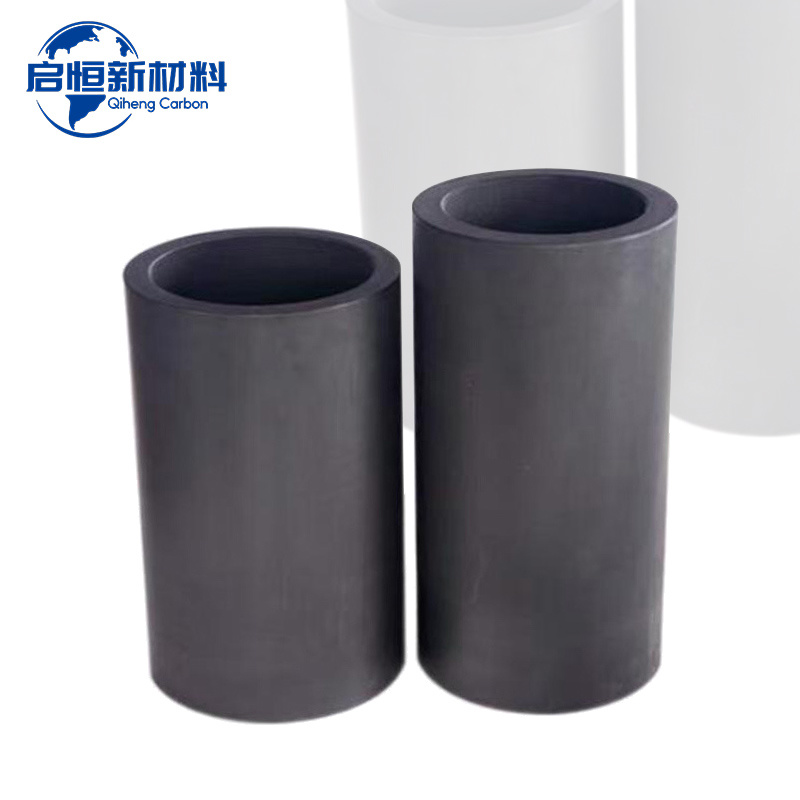

Graphite crucibles are high-temperature containers used for melting metals and alloys. Their exceptional thermal stability and resistance to chemical reactions make them a favored choice in various industries. However, the production and usage of these crucibles can lead to significant environmental challenges. Understanding these challenges is crucial for developing sustainable practices that minimize their ecological footprint.

2. The Production Process of Graphite Crucibles

The production of graphite crucibles involves several stages, each with its unique environmental considerations. The primary steps include:

2.1 Raw Material Extraction

The process begins with the extraction of raw materials, primarily natural graphite. This extraction can have severe environmental impacts, including habitat destruction and greenhouse gas emissions.

2.2 Manufacturing Process

Once raw materials are sourced, they undergo various processes, such as crushing, grinding, and shaping. The energy-intensive nature of these processes contributes further to the environmental burden, highlighting the need for more efficient techniques.

2.3 Quality Control

Quality control measures ensure the crucibles meet industry standards. However, these measures can also contribute to waste generation, necessitating careful management practices.

3. Resource Sourcing: The Environmental Aspect

Resource sourcing for graphite crucibles is a significant environmental concern. The mining of natural graphite often results in the depletion of local resources and disruption of ecosystems. Additionally, the carbon footprint associated with transporting these materials can further exacerbate environmental issues.

3.1 Sustainable Mining Practices

To mitigate these impacts, it is essential to adopt sustainable mining practices. Techniques such as responsible sourcing, land rehabilitation, and minimizing water usage can significantly reduce the ecological footprint of graphite extraction.

4. Applications of Graphite Crucibles

Graphite crucibles are utilized across various sectors, including:

4.1 Metallurgy

In metallurgy, graphite crucibles are indispensable for melting high-temperature metals. Their ability to withstand extreme conditions makes them ideal for this application.

4.2 Electronics

In the electronics sector, graphite crucibles are used for producing semiconductors and photovoltaic cells, proving their versatility and importance in modern technology.

5. Waste Management Practices in the Graphite Industry

Effective waste management is critical in minimizing the environmental impact of graphite crucible production. The industry faces challenges such as:

5.1 Solid Waste Generation

Solid waste generated during production needs careful handling and disposal to avoid contaminating soil and water sources.

5.2 Emission Control

Air emissions from manufacturing processes contribute to pollution. Implementing stringent emission control measures can help mitigate these impacts.

6. Sustainable Alternatives to Traditional Graphite Crucibles

As environmental concerns mount, the search for sustainable alternatives to traditional graphite crucibles intensifies. Some viable options include:

6.1 Silicon Carbide Crucibles

Silicon carbide crucibles offer enhanced thermal conductivity and strength, serving as a promising alternative to graphite crucibles.

6.2 Recycled Graphite Crucibles

Utilizing recycled graphite can significantly reduce the demand for new raw materials, lessening the environmental impact of production.

7. Regulatory Framework Governing Graphite Production

Government regulations play a crucial role in shaping the practices of the graphite industry. Compliance with environmental laws and standards ensures that companies take necessary actions to minimize their ecological footprint.

7.1 Environmental Assessments

Conducting environmental assessments prior to mining or production can help identify potential impacts and implement mitigation strategies.

7.2 Industry Standards

Adhering to industry standards, such as ISO certifications, can promote sustainable practices and improve the overall environmental performance of the graphite sector.

8. Future Trends in Graphite Crucible Production and Environmental Impact

The future of graphite crucibles is poised for change, driven by technological advancements and changing regulations. Key trends include:

8.1 Emphasis on Sustainability

As industries globally strive for sustainability, we can expect a shift towards more eco-friendly production methods and materials.

8.2 Innovation in Recycling Technologies

Investment in recycling technologies can lead to more efficient use of resources and reduced waste in the graphite crucible manufacturing process.

9. Conclusion

Graphite crucibles are essential components in various industries, yet their production and usage come with significant environmental challenges. By understanding the intricacies of their production processes, resource sourcing, and waste management practices, we can identify areas for improvement. The pursuit of sustainable alternatives and adherence to regulatory frameworks will be vital in reducing the ecological footprint of graphite crucibles. As we move forward, innovation will be key in ensuring that the industry not only meets the growing demand for graphite crucibles but does so in a manner that preserves the environment for future generations.

10. Frequently Asked Questions

What are graphite crucibles used for?

Graphite crucibles are primarily used for melting metals and alloys in high-temperature applications, including metallurgy and electronics manufacturing.

What is the environmental impact of graphite mining?

Graphite mining can lead to habitat destruction, resource depletion, and significant greenhouse gas emissions, making it crucial to adopt sustainable practices.

Are there sustainable alternatives to graphite crucibles?

Yes, options such as silicon carbide crucibles and recycled graphite crucibles offer more sustainable solutions that can reduce environmental impact.

How can the graphite industry improve waste management?

Implementing effective solid waste disposal methods, controlling emissions, and recycling can significantly enhance waste management practices in the graphite industry.

What regulations govern graphite production?

Environmental regulations and industry standards, such as ISO certifications, guide the practices of the graphite industry to minimize its ecological footprint.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries