Graphite Electrode Trends: Insights from Industry Experts

Summary:

Graphite Electrode Trends: Insights from Industry Experts

Table of Contents

1. Introduction to Graphite Electrodes

2. Market Overview of Graphite Electrodes

3. Key Trends Influencing the Graphite Electrode Market

4. Technological Advancements in Graphite Electrode Production

5. Environmental Considerations and Sustainability in Graphite Production

6. Insights from Indust

Graphite Electrode Trends: Insights from Industry Experts

Table of Contents

- 1. Introduction to Graphite Electrodes

- 2. Market Overview of Graphite Electrodes

- 3. Key Trends Influencing the Graphite Electrode Market

- 4. Technological Advancements in Graphite Electrode Production

- 5. Environmental Considerations and Sustainability in Graphite Production

- 6. Insights from Industry Experts

- 7. Future Outlook for Graphite Electrodes

- 8. Conclusion

- 9. FAQs

1. Introduction to Graphite Electrodes

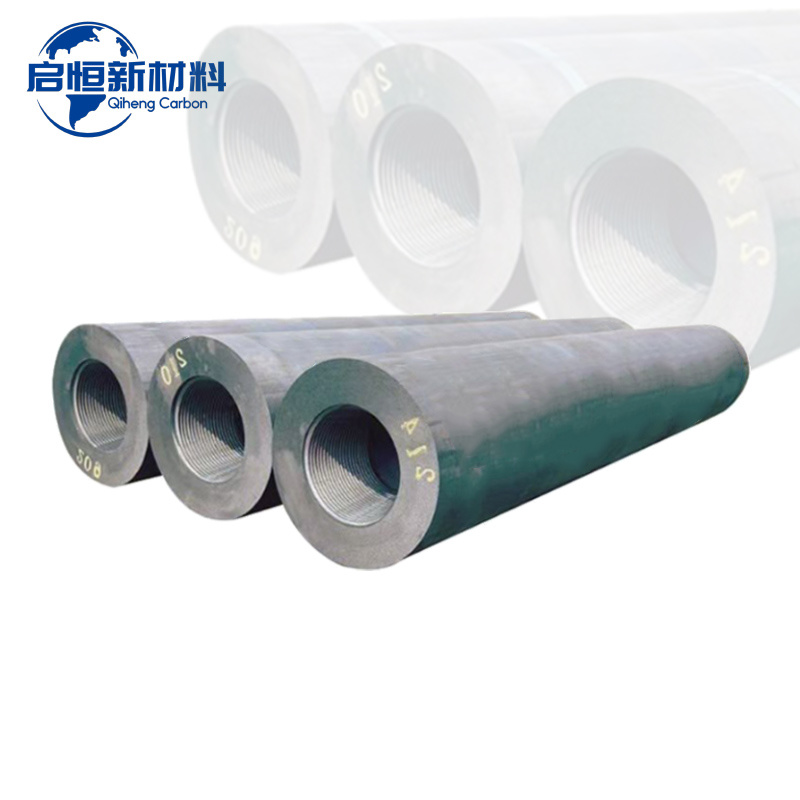

Graphite electrodes play a crucial role in various industries, primarily in electric arc furnaces (EAF) for steel production. They are essential for conducting electricity and facilitating the melting process. As industries shift towards more sustainable practices, the demand for high-quality graphite electrodes has skyrocketed. This article delves into the latest trends in the graphite electrode market, informed by insights from industry experts.

2. Market Overview of Graphite Electrodes

The global graphite electrode market has experienced significant growth due to rising steel production and increasing demand from the automotive and aerospace sectors. According to recent reports, the market is expected to grow at a CAGR of approximately 5.6% from 2023 to 2030. Factors driving this growth include innovations in electrode manufacturing processes, the increasing popularity of EAFs, and a growing focus on recycling scrap steel.

The Demand Surge in the Steel Industry

The demand for graphite electrodes is primarily driven by the burgeoning steel industry. With the growing need for steel in construction, infrastructure, and automotive applications, the EAF process has become increasingly popular, leading to a parallel rise in graphite electrode demand.

Regional Market Dynamics

Asia-Pacific dominates the graphite electrode market due to rapid industrialization and infrastructure development in countries like China and India. North America and Europe are also significant markets, focusing on the adoption of eco-friendly practices and advanced technologies in electrode production.

3. Key Trends Influencing the Graphite Electrode Market

Several trends are shaping the graphite electrode landscape, influencing everything from production methods to end-user applications.

Innovation in Manufacturing Techniques

Manufacturers are increasingly adopting innovative production techniques to enhance the quality and performance of graphite electrodes. Techniques such as vibration molding and advanced roasting processes are gaining traction, resulting in higher density and lower electrical resistance.

Shift Towards Eco-Friendly Materials

The industry is witnessing a shift towards using eco-friendly and recycled materials in the production of graphite electrodes. This not only reduces environmental impact but also aligns with global sustainability goals. Companies are investing in research to develop alternatives that maintain performance while being environmentally responsible.

4. Technological Advancements in Graphite Electrode Production

Technology plays a pivotal role in the evolution of graphite electrode production, impacting everything from material selection to process optimization.

Automation and Industry 4.0

The integration of automation and Industry 4.0 technologies is revolutionizing the graphite electrode manufacturing process. Automated systems improve efficiency and precision, minimizing waste and enhancing product quality. Smart manufacturing techniques, utilizing IoT devices and AI, allow real-time monitoring and data analysis, optimizing production workflows.

Research and Development in Graphite Quality

Ongoing R&D efforts are focused on improving the quality and performance characteristics of graphite electrodes. Innovations in material science are leading to the development of electrodes that can withstand higher temperatures and deliver better conductivity, thereby improving overall efficiency in steel production.

5. Environmental Considerations and Sustainability in Graphite Production

As concerns about climate change and environmental sustainability rise, the graphite industry is under pressure to adopt greener practices.

Reducing Carbon Footprint

Manufacturers are actively working to reduce their carbon footprint by implementing cleaner production techniques and investing in renewable energy sources. The use of recycled materials in electrode production is also a key focus, as it not only reduces waste but also conserves natural resources.

Regulatory Compliance and Industry Standards

Compliance with international environmental regulations is increasingly important for graphite electrode manufacturers. Adhering to industry standards not only ensures sustainability but also enhances brand reputation and market competitiveness.

6. Insights from Industry Experts

To provide valuable insights, we consulted several industry experts and thought leaders. Their perspectives shed light on current challenges and future directions for the graphite electrode market.

Experts on Market Challenges

Many experts identify fluctuating raw material prices as a significant challenge for manufacturers. As demand increases, sourcing high-quality materials can become increasingly difficult, impacting production costs and overall profitability.

Predictions for Industry Growth

Experts predict robust growth in the graphite electrode market, driven by advancements in technology and increasing adoption of electric arc furnaces. The transition towards greener technologies in steel production will further catalyze this growth.

7. Future Outlook for Graphite Electrodes

Looking forward, the graphite electrode market is poised for continued evolution and transformation.

Emerging Markets and Opportunities

Emerging markets in Africa and Southeast Asia present significant opportunities for growth. As these regions industrialize, the demand for steel and, consequently, graphite electrodes is expected to rise, paving the way for new market entrants and innovations.

Investment in Research and Development

Investment in R&D will be critical for companies aiming to stay competitive. Developing advanced materials and production techniques will not only enhance product offerings but also support sustainability initiatives.

8. Conclusion

The graphite electrode market is undergoing significant transformations driven by technological advancements, sustainability concerns, and evolving market demands. As industries continue to innovate and adapt, staying informed of the latest trends and insights is crucial for stakeholders in the graphite sector. By embracing change and investing in sustainable practices, companies can position themselves for success in this dynamic landscape.

9. FAQs

What are graphite electrodes used for?

Graphite electrodes are primarily used in electric arc furnaces for steel production, facilitating the melting process by conducting electricity.

What factors are driving the demand for graphite electrodes?

The increasing demand for steel, particularly from the construction and automotive sectors, along with the transition to electric arc furnaces, is driving the demand for graphite electrodes.

How are manufacturers addressing environmental concerns in graphite production?

Manufacturers are adopting eco-friendly practices, such as using recycled materials and implementing cleaner production techniques to reduce the carbon footprint.

What technological advancements are impacting graphite electrode production?

Innovations in automation, Industry 4.0 technologies, and advanced material science are enhancing the efficiency and quality of graphite electrode production.

What is the future outlook for the graphite electrode market?

The graphite electrode market is expected to grow significantly, driven by advancements in technology, sustainability initiatives, and emerging markets in developing regions.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property