Why Graphite Square is Essential for Non-Metallic Mineral Products

Summary:

Why Graphite Square is Essential for Non-Metallic Mineral Products

Table of Contents

Introduction to Graphite Squares

Understanding Graphite: A Unique Non-Metallic Mineral

Properties of Graphite That Make it Indispensable

Applications of Graphite Squares in Various Industries

Advantages of Using Graphite Squares in Non-Metallic Mineral Products

Sustainability Aspects of Graphite Produ

Why Graphite Square is Essential for Non-Metallic Mineral Products

Table of Contents

- Introduction to Graphite Squares

- Understanding Graphite: A Unique Non-Metallic Mineral

- Properties of Graphite That Make it Indispensable

- Applications of Graphite Squares in Various Industries

- Advantages of Using Graphite Squares in Non-Metallic Mineral Products

- Sustainability Aspects of Graphite Production

- Future Trends in Graphite Square Utilization

- Conclusion: The Importance of Graphite Squares in Modern Industries

- FAQs: Common Questions About Graphite Squares

Introduction to Graphite Squares

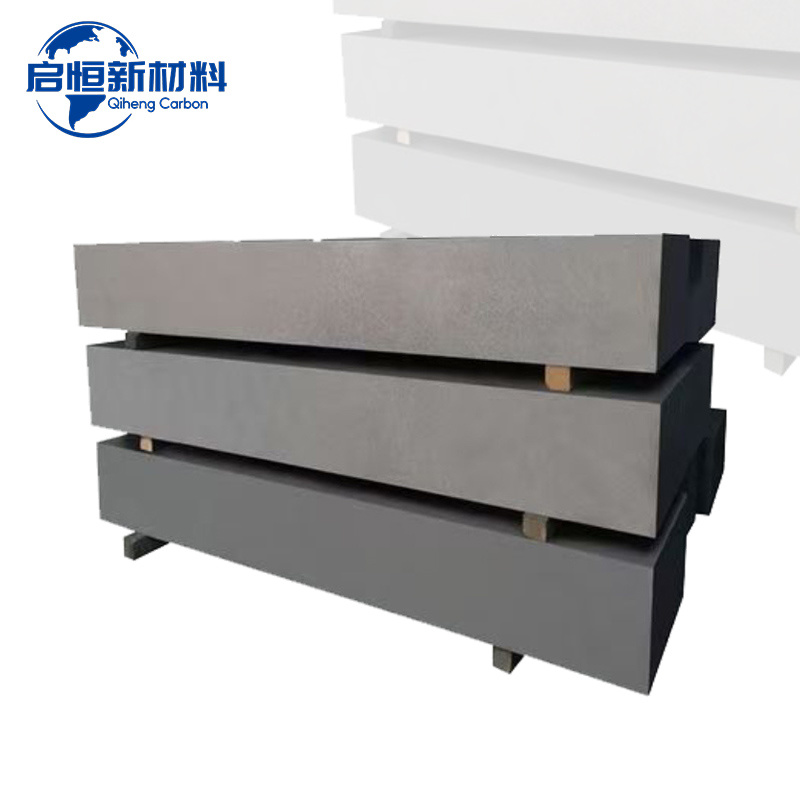

Graphite squares are becoming increasingly important in the realm of **non-metallic mineral products**. These materials are not only versatile but also essential in various applications across numerous industries. As the demand for high-performance materials rises, understanding the significance of graphite squares can help businesses innovate and remain competitive. This article delves into the properties, applications, and advantages of graphite squares, shedding light on their vital role in modern manufacturing.

Understanding Graphite: A Unique Non-Metallic Mineral

Graphite is a non-metallic mineral composed primarily of carbon atoms arranged in a crystalline structure. This arrangement imparts several unique properties, including excellent conductivity, lubricity, and thermal resistance. Graphite is often found in various forms, including natural and synthetic varieties, and can be processed into **graphite squares** for specific applications. The versatility of graphite makes it suitable for a range of products, from batteries to lubricants, and even in the production of advanced materials.

The Formation and Types of Graphite

There are two primary types of graphite: **natural graphite** and **synthetic graphite**. Natural graphite is mined from the earth, while synthetic graphite is produced through high-temperature processes involving carbon-rich materials. Each type has distinct characteristics and applications, but both can be shaped into squares, enhancing their usefulness in various industries.

Properties of Graphite That Make it Indispensable

The properties of graphite squares contribute significantly to their demand in the non-metallic mineral products sector. Here are some key attributes that make graphite unique:

1. High Thermal Conductivity

Graphite is known for its exceptional thermal conductivity, making it ideal for applications that require efficient heat dissipation. This property is particularly important in the electronics and automotive industries, where overheating can lead to device failure.

2. Electrical Conductivity

Graphite squares exhibit excellent electrical conductivity, which is crucial in battery technology and electrical components. As the world moves towards renewable energy sources, the demand for conductive materials like graphite is increasing.

3. Lubricating Properties

The natural lubricating qualities of graphite make it a preferred choice in applications where friction reduction is essential. This property is beneficial in machinery, automotive parts, and even in personal care products like deodorants.

4. Chemical Resistance

Graphite is highly resistant to chemical attack, which allows it to be used in harsh environments without degrading. This makes it suitable for applications in the chemical industry, particularly in manufacturing equipment that handles corrosive substances.

5. Lightweight Yet Strong

Despite being lightweight, graphite possesses significant strength and durability. This characteristic makes it an attractive option for manufacturers looking to reduce weight without compromising on performance.

Applications of Graphite Squares in Various Industries

Graphite squares find applications in a multitude of sectors, each capitalizing on their unique properties. Below are some industries that benefit from these versatile materials:

1. Electronics Industry

Graphite squares are extensively used in the electronics industry, particularly in producing batteries, capacitors, and conductive coatings. Their electrical conductivity ensures efficient energy transfer and storage, making them essential in modern electronic devices.

2. Automotive Sector

In the automotive sector, graphite squares are utilized in brake linings, lubricants, and gaskets. Their heat resistance and lubricating properties contribute to the efficiency and safety of vehicles, promoting smoother operations.

3. Renewable Energy

The shift towards renewable energy has amplified the demand for graphite in manufacturing lithium-ion batteries for electric vehicles (EVs) and renewable energy storage systems. Graphite squares play a crucial role in enhancing battery performance and longevity.

4. Aerospace and Defense

In the aerospace and defense industries, graphite's lightweight and strong properties are invaluable. Graphite squares are used in various applications, including thermal protection systems and structural components, where weight reduction is critical.

5. Industrial Applications

Graphite squares are widely used as lubricants in machinery and equipment, reducing wear and tear while enhancing efficiency. Their chemical resistance also makes them suitable for manufacturing equipment in the chemical industry.

Advantages of Using Graphite Squares in Non-Metallic Mineral Products

The incorporation of graphite squares in non-metallic mineral products offers several advantages, providing manufacturers with a competitive edge. Here are some notable benefits:

1. Improved Performance

Graphite enhances the performance of non-metallic products by providing properties such as conductivity, strength, and resistance to wear. This results in superior product quality and longevity.

2. Cost-Effectiveness

Using graphite squares can lead to cost savings in manufacturing processes. Their durability reduces maintenance costs, while their efficient thermal and electrical properties improve energy efficiency.

3. Versatile Applications

Graphite squares can be tailored for various applications, making them suitable for different industries. This versatility allows manufacturers to create specialized products that meet specific market demands.

4. Environmental Benefits

Graphite is a natural resource, and when sourced sustainably, it can contribute to eco-friendly manufacturing practices. Its long lifespan and recyclability further enhance its environmental credentials.

Sustainability Aspects of Graphite Production

Sustainability is a key consideration in the mining and processing of graphite. As the demand for non-metallic mineral products increases, ensuring environmentally responsible practices is essential.

1. Responsible Mining Practices

Promoting responsible mining practices can help minimize the environmental impact of graphite extraction. This includes reducing land disturbance and ensuring that ecosystems are preserved.

2. Recycling and Reusability

Graphite can be recycled and reused, reducing the need for new material extraction. This not only conserves resources but also minimizes waste, making it a sustainable choice for manufacturers.

3. Regulatory Compliance

Adhering to environmental regulations is essential for graphite producers. Compliance ensures that the production process is environmentally friendly, maintaining the integrity of natural ecosystems.

Future Trends in Graphite Square Utilization

The future of graphite squares looks promising, with several trends shaping their use in non-metallic mineral products.

1. Increased Demand in Electric Vehicles

The growth of the electric vehicle market is expected to drive demand for graphite squares, particularly in battery manufacturing. As more consumers shift towards sustainable transportation, the need for high-quality graphite will continue to rise.

2. Innovations in Graphite Processing

Advancements in processing technologies will lead to improved performance characteristics of graphite squares. Innovations may result in the development of new applications and increased efficiency in production.

3. Focus on Sustainability

As industries become more environmentally conscious, the focus on sustainable sourcing and production of graphite will intensify. This trend will encourage manufacturers to adopt greener practices, enhancing the overall sustainability of non-metallic products.

Conclusion: The Importance of Graphite Squares in Modern Industries

Graphite squares play an essential role in the production of non-metallic mineral products, thanks to their unique properties and versatile applications. From electronics to automotive and renewable energy, their contributions are invaluable. As industries continue to innovate and pursue sustainability, the demand for graphite squares is set to rise, underscoring their significance in modern manufacturing.

FAQs: Common Questions About Graphite Squares

1. What are graphite squares used for?

Graphite squares are used in various applications across multiple industries, including batteries, automotive parts, lubricants, and electronics due to their excellent conductivity and lubricating properties.

2. How is synthetic graphite different from natural graphite?

Synthetic graphite is produced through high-temperature processes involving carbon-rich materials, while natural graphite is mined from the earth. Synthetic graphite often has more uniform properties and can be tailored for specific applications.

3. Are graphite squares environmentally friendly?

When sourced responsibly, graphite squares can be environmentally friendly. They can be recycled and reused, which reduces the demand for new material extraction and minimizes waste.

4. What advantages do graphite squares offer in manufacturing?

Graphite squares provide enhanced performance, cost-effectiveness, versatility, and environmental benefits, making them a preferred choice for many manufacturers.

5. What trends are shaping the future of graphite squares?

Key trends include increased demand in electric vehicles, innovations in graphite processing, and a stronger focus on sustainability in production practices.

With the growing significance of graphite squares in non-metallic mineral products, understanding their properties and applications is crucial for industries looking to innovate and thrive.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property