The Vital Importance of Graphite Crucibles in Casting Industrial Components

Summary:

The Vital Importance of Graphite Crucibles in Casting Industrial Components

Introduction to Graphite Crucibles

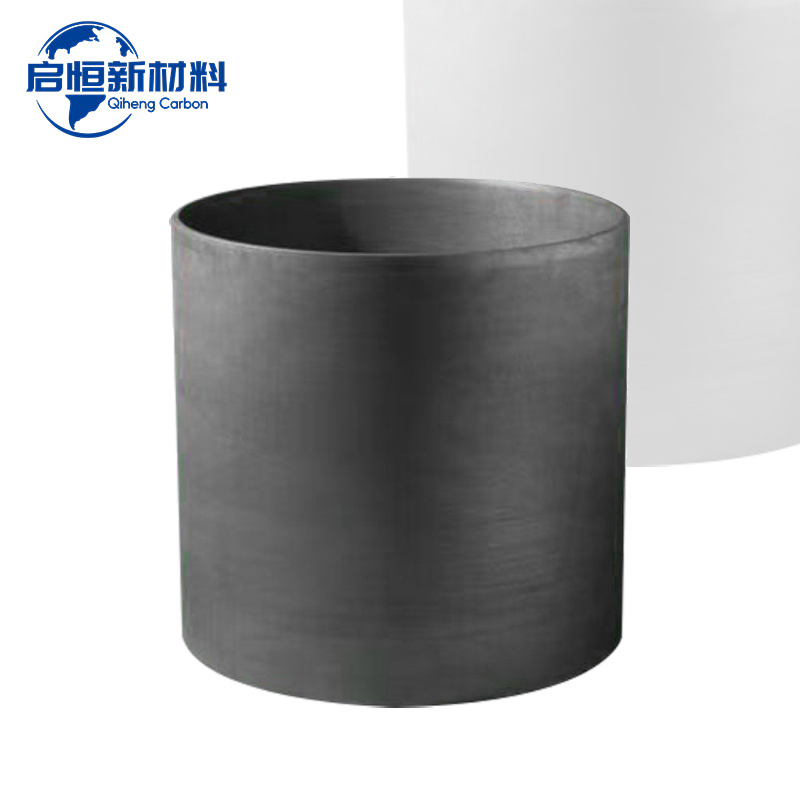

In the realm of metallurgy, **graphite crucibles** serve as essential tools for melting various metals and alloys. These specialized containers facilitate high-temperature processes, enabling the efficient casting of industrial components. As industries continue to evolve, the demand fo

The Vital Importance of Graphite Crucibles in Casting Industrial Components

Introduction to Graphite Crucibles

In the realm of metallurgy, **graphite crucibles** serve as essential tools for melting various metals and alloys. These specialized containers facilitate high-temperature processes, enabling the efficient casting of industrial components. As industries continue to evolve, the demand for effective casting methods increases, making graphite crucibles integral to modern manufacturing practices.

The Unique Properties of Graphite

To understand the significance of graphite crucibles, it's crucial to delve into the unique properties of graphite itself. Here are the key characteristics that make this material particularly suited for casting applications:

High Thermal Conductivity

Graphite exhibits exceptional thermal conductivity, allowing it to withstand and distribute heat evenly during the melting process. This property ensures that the metal reaches its melting point uniformly, resulting in a **high-quality casting**.

Resistance to Thermal Shock

One of the standout features of graphite is its remarkable resistance to thermal shock. This means that it can endure rapid temperature changes without cracking or deforming, which is essential in the high-stakes environment of metal casting.

Low Coefficient of Thermal Expansion

Graphite has a low coefficient of thermal expansion, allowing it to maintain its shape and structural integrity even under intense heat. This stability is vital for producing precise components that meet stringent industry specifications.

Non-Wetting Characteristics

Graphite's non-wetting nature minimizes the risk of metal adhesion to the crucible's surface. This property is particularly beneficial for ensuring easy removal of cast components, reducing production downtime and enhancing overall efficiency.

Applications of Graphite Crucibles

Graphite crucibles are employed across various industries due to their versatility and effectiveness. Here are some common applications:

Foundries

In foundries, graphite crucibles are used for melting ferrous and non-ferrous metals, including aluminum, copper, and bronze. Their ability to handle high temperatures and resist oxidation makes them an ideal choice for producing intricate castings.

Aerospace and Automotive Manufacturing

The aerospace and automotive sectors rely heavily on precision components made from high-performance alloys. Graphite crucibles enable the production of lightweight yet strong parts that meet rigorous safety and performance standards.

Jewelry Casting

In the jewelry industry, graphite crucibles facilitate the melting of precious metals like gold and silver. The fine detail and finish achieved through this process are paramount for creating exquisite jewelry pieces.

Benefits of Using Graphite Crucibles

The adoption of graphite crucibles in casting processes comes with several benefits that enhance productivity and product quality:

Durability and Longevity

Graphite crucibles are known for their durability, often lasting longer than traditional ceramic alternatives. This longevity translates into cost savings for manufacturers, as they require less frequent replacement.

Enhanced Quality of Castings

The unique properties of graphite contribute to superior casting quality. This results in fewer defects and inconsistencies, leading to higher customer satisfaction and reduced waste.

Energy Efficiency

By facilitating faster melting times and better heat retention, graphite crucibles promote energy efficiency. Manufacturers can reduce operational costs while also minimizing their environmental footprint.

Choosing the Right Graphite Crucible

Selecting the appropriate graphite crucible is critical for achieving optimal results. Here are some factors to consider:

Crucible Size and Shape

The size and shape of the crucible must correspond to the volume and type of metal being melted. Ensuring a proper fit minimizes the risk of overflow and enhances heat retention.

Grade of Graphite

Different applications require different grades of graphite. Higher purity grades are necessary for applications demanding superior quality, while lower grades may suffice for more general uses.

Thermal Conductivity Ratings

Understanding the thermal conductivity ratings of various crucibles helps manufacturers choose the best option for their specific melting needs. Higher ratings lead to improved melting efficiency.

Maintenance and Care for Graphite Crucibles

To maximize the lifespan of graphite crucibles, proper maintenance is essential. Here are some best practices:

Cleaning Techniques

After each use, it's vital to clean the crucibles thoroughly. A gentle brush or a cloth can remove any residual metal or debris. Avoid using harsh chemicals that may damage the graphite.

Proper Storage

Store graphite crucibles in a cool, dry place to prevent moisture absorption, which can negatively affect their performance. Using protective covers can further enhance their longevity.

Regular Inspections

Conducting regular inspections for cracks or deformities helps in identifying potential issues early. Timely replacements can prevent costly production delays.

The Future of Graphite Crucibles in Industry

As industries continue to innovate, the role of graphite crucibles is expected to evolve. The move towards **sustainable manufacturing** practices and the development of new materials may influence the design and functionality of future crucibles.

Emerging Technologies

Advancements in technology, including the integration of digital monitoring systems, are likely to enhance the performance and efficiency of graphite crucibles. These systems can provide real-time data, optimizing the casting process further.

Environmental Considerations

With greater emphasis on sustainability, manufacturers are increasingly looking at how to reduce waste and energy consumption. Graphite crucibles align well with these goals due to their durability and efficiency.

Frequently Asked Questions (FAQs)

1. What are graphite crucibles made of?

Graphite crucibles are primarily made from high-purity graphite. The specific composition can vary based on the intended application and required properties.

2. Can graphite crucibles be reused?

Yes, graphite crucibles are designed for multiple uses, provided they are maintained properly. Regular cleaning and inspections can prolong their lifespan significantly.

3. How do I choose the right size graphite crucible?

Selecting the correct size involves considering the volume of metal to be melted and the specific casting requirements. Manufacturers often provide guidelines to assist in this decision.

4. Are there any alternatives to graphite crucibles?

While there are alternatives such as ceramic crucibles, graphite is often preferred due to its superior thermal properties and durability.

5. What industries primarily use graphite crucibles?

Industries such as foundry, aerospace, automotive, and jewelry manufacturing extensively rely on graphite crucibles for their casting processes.

Conclusion

Graphite crucibles play an indispensable role in the casting of industrial components, offering unique properties that enhance the efficiency and quality of metal melting processes. As industries continue to advance and seek more sustainable manufacturing practices, the importance of graphite crucibles will only grow. By understanding their applications, benefits, and proper maintenance, manufacturers can ensure high-quality outputs that meet the demands of modern industries. With ongoing innovations and a shift towards eco-friendly practices, the future of graphite crucibles looks promising, solidifying their status as pivotal tools in the world of metallurgy.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property