The Essential Guide to Calcined Petroleum Coke: Properties, Uses, and Industry Insights

Summary:

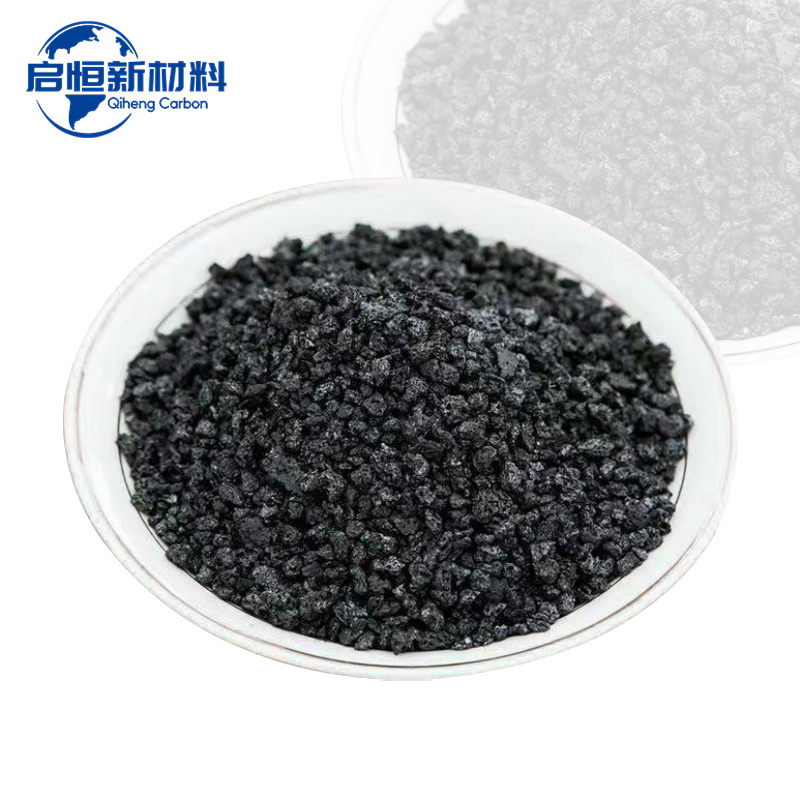

Calcined petroleum coke (CPC) is a high-purity carbon material produced from the calcination of green petroleum coke, a byproduct of oil refining. The calcination process involves heating the green coke to high temperatures (around 1200°C to 1400°C) to drive off volatile materials, resulting in a product with enhanced conductivity and lower impurities. This unique transformation not only improves

Calcined petroleum coke (CPC) is a high-purity carbon material produced from the calcination of green petroleum coke, a byproduct of oil refining. The calcination process involves heating the green coke to high temperatures (around 1200°C to 1400°C) to drive off volatile materials, resulting in a product with enhanced conductivity and lower impurities. This unique transformation not only improves its physical properties but also makes CPC an ideal candidate for multiple applications.

One of the primary uses of calcined petroleum coke is in the aluminum industry, where it serves as a crucial ingredient in the production of anodes for aluminum smelting. The high carbon content and electrical conductivity of CPC make it a preferred choice for this application, enabling efficient electrolysis during the aluminum extraction process. Additionally, calcined petroleum coke finds its way into the manufacturing of steel and titanium dioxide, where it contributes to the production of high-quality alloys and pigments.

Moreover, CPC is utilized in the production of various carbon-containing materials, including graphite electrodes and carbon additives. The demand for these products in sectors such as lithium-ion battery manufacturing has surged, further underscoring the versatility of calcined petroleum coke in modern applications. As industries continue to innovate, the role of CPC is expected to expand, making it increasingly relevant in emerging technologies.

Another important aspect of calcined petroleum coke is its environmental considerations. The production process must comply with stringent regulations to minimize emissions and ensure responsible sourcing. Many companies are investing in sustainable practices, including the utilization of cleaner technologies and waste reduction strategies, to enhance the environmental footprint of CPC production.

In summary, calcined petroleum coke is a vital material with diverse applications across various industries, particularly in aluminum production and carbon manufacturing. Its unique properties result from an intricate production process that emphasizes purity and conductivity. As the demand for high-performance materials continues to grow, understanding the role of CPC in industrial applications is essential for professionals in the chemical and petroleum sectors. Staying informed about developments in this field will not only aid in strategic decision-making but also contribute to a more sustainable future in industrial practices.

One of the primary uses of calcined petroleum coke is in the aluminum industry, where it serves as a crucial ingredient in the production of anodes for aluminum smelting. The high carbon content and electrical conductivity of CPC make it a preferred choice for this application, enabling efficient electrolysis during the aluminum extraction process. Additionally, calcined petroleum coke finds its way into the manufacturing of steel and titanium dioxide, where it contributes to the production of high-quality alloys and pigments.

Moreover, CPC is utilized in the production of various carbon-containing materials, including graphite electrodes and carbon additives. The demand for these products in sectors such as lithium-ion battery manufacturing has surged, further underscoring the versatility of calcined petroleum coke in modern applications. As industries continue to innovate, the role of CPC is expected to expand, making it increasingly relevant in emerging technologies.

Another important aspect of calcined petroleum coke is its environmental considerations. The production process must comply with stringent regulations to minimize emissions and ensure responsible sourcing. Many companies are investing in sustainable practices, including the utilization of cleaner technologies and waste reduction strategies, to enhance the environmental footprint of CPC production.

In summary, calcined petroleum coke is a vital material with diverse applications across various industries, particularly in aluminum production and carbon manufacturing. Its unique properties result from an intricate production process that emphasizes purity and conductivity. As the demand for high-performance materials continues to grow, understanding the role of CPC in industrial applications is essential for professionals in the chemical and petroleum sectors. Staying informed about developments in this field will not only aid in strategic decision-making but also contribute to a more sustainable future in industrial practices.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property