Why Choosing the Right Connector Matters: A Focus on Graphite Electrode Connectors

Summary:

Why Choosing the Right Connector Matters: A Focus on Graphite Electrode Connectors

Table of Contents

1. Understanding Connectors in Electrical Systems

2. The Role of Graphite Electrode Connectors

3. Key Characteristics of Graphite Electrode Connectors

4. Applications of Graphite Electrode Connectors

4.1. Industrial Applications

4.2. Commercial Applications

5. Factors to Consider When C

Why Choosing the Right Connector Matters: A Focus on Graphite Electrode Connectors

Table of Contents

1. Understanding Connectors in Electrical Systems

2. The Role of Graphite Electrode Connectors

3. Key Characteristics of Graphite Electrode Connectors

4. Applications of Graphite Electrode Connectors

4.1. Industrial Applications

4.2. Commercial Applications

5. Factors to Consider When Choosing Graphite Electrode Connectors

5.1. Conductivity

5.2. Temperature Resistance

5.3. Mechanical Strength

6. Common Types of Graphite Electrode Connectors

6.1. Standard Graphite Connectors

6.2. High-Performance Connectors

7. Installation Best Practices for Graphite Electrode Connectors

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Understanding Connectors in Electrical Systems

Connectors are vital components in electrical systems, serving as junctions between various cables and devices. They facilitate the flow of electricity, ensuring reliable connections that can withstand environmental conditions and mechanical stress. In the realm of electrical engineering, connectors come in diverse shapes and sizes, each serving a specific purpose and application. Selecting the right connector is crucial for maintaining system integrity, optimizing performance, and enhancing safety.

2. The Role of Graphite Electrode Connectors

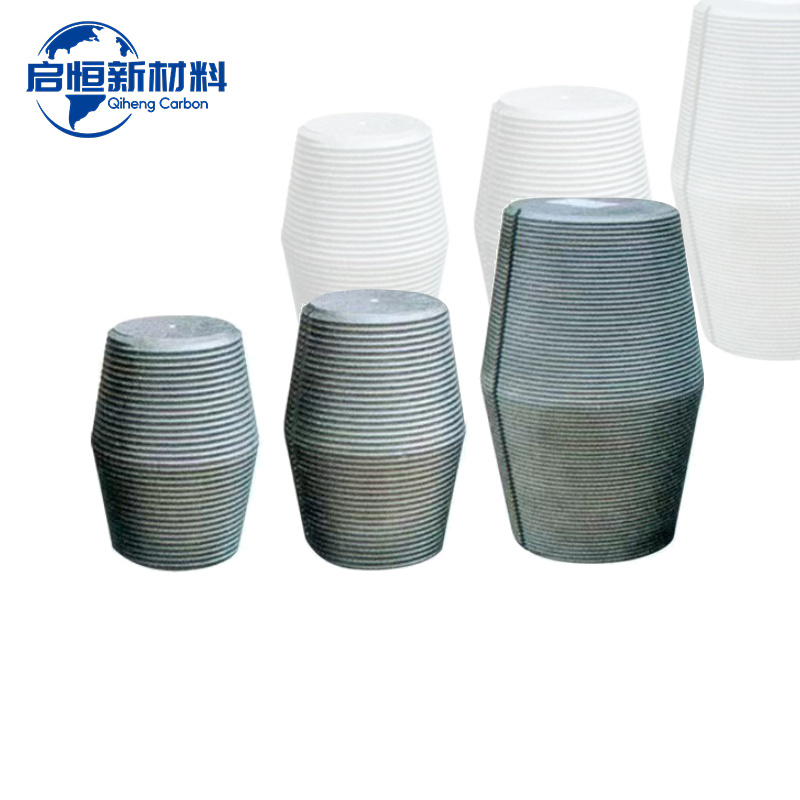

Graphite electrode connectors play a specialized role in electrical systems, particularly in high-temperature and high-performance environments. These connectors are specifically designed to handle the unique demands of graphite electrodes used in electric arc furnaces, foundries, and various industrial processes. By providing a robust connection, they ensure efficient energy transfer and contribute to the overall functionality of the system.

3. Key Characteristics of Graphite Electrode Connectors

When evaluating graphite electrode connectors, several characteristics come into play:

- **Conductivity**: The ability to conduct electricity effectively is paramount. Graphite's inherent properties make it an excellent conductor, ensuring minimal energy loss during transmission.

- **Thermal Resistance**: High operating temperatures are common in environments utilizing graphite electrodes. Thus, connectors must withstand extreme heat without degrading in performance.

- **Mechanical Strength**: Connectors must endure mechanical stress and potential vibrations. A robust construction ensures longevity and reliability, reducing the likelihood of connection failure.

- **Corrosion Resistance**: In many applications, connectors face exposure to harsh chemicals and environmental conditions. The right material choice can prevent corrosion and deterioration, maintaining connection integrity over time.

4. Applications of Graphite Electrode Connectors

Graphite electrode connectors find applications across various industries, leveraging their unique properties to meet demanding requirements.

4.1. Industrial Applications

In industrial settings, graphite electrode connectors are predominantly utilized in electric arc furnaces for steelmaking. Here, they connect electrodes to the power source, facilitating the intense electrical currents required for melting scrap metal. The high-temperature tolerance of these connectors ensures a consistent operation, even in the most challenging conditions.

4.2. Commercial Applications

Beyond industrial use, graphite electrode connectors also play a role in commercial applications such as battery systems, renewable energy solutions, and advanced manufacturing processes. Their ability to handle high currents makes them suitable for electric vehicles and energy storage systems where efficient energy transfer is critical.

5. Factors to Consider When Choosing Graphite Electrode Connectors

Selecting the right graphite electrode connector involves careful consideration of various factors to ensure compatibility and performance.

5.1. Conductivity

Evaluate the electrical conductivity of the connector material. Optimal conductivity ensures low resistance and efficient energy transfer, crucial for high-performance applications. Look for materials with a proven track record in demanding environments.

5.2. Temperature Resistance

Assess the temperature rating of the connectors. High-temperature applications require connectors that can function effectively without degradation. Make sure to choose connectors rated for the maximum temperatures expected in your application.

5.3. Mechanical Strength

Consider the mechanical demands the connectors will face. Choose connectors with adequate mechanical strength to withstand vibrations and movement without compromising the electrical connection.

6. Common Types of Graphite Electrode Connectors

Graphite electrode connectors come in various types, each serving specific needs within electrical systems.

6.1. Standard Graphite Connectors

These connectors typically feature a simple design suitable for general applications. They offer a good balance of conductivity and mechanical strength, making them versatile for various uses.

6.2. High-Performance Connectors

Designed for extreme conditions, high-performance connectors use advanced materials and construction techniques. These connectors excel in high-temperature and high-stress environments, providing enhanced reliability and efficiency.

7. Installation Best Practices for Graphite Electrode Connectors

To maximize the performance of graphite electrode connectors, follow these installation best practices:

- **Proper Torque Specifications**: Apply the correct torque when connecting terminals to ensure a secure connection. Over-tightening can damage the connector, while under-tightening may lead to loose connections.

- **Environmental Considerations**: Install connectors in environments that minimize exposure to extreme conditions whenever possible. Utilize protective measures such as enclosures or coatings to extend the lifespan of connectors.

- **Regular Maintenance Checks**: Implement routine inspections to identify wear or potential issues. Prompt maintenance can prevent failures and extend the lifespan of both connectors and connected devices.

8. Frequently Asked Questions (FAQs)

**Q1: What materials are commonly used in graphite electrode connectors?**

A1: Graphite electrode connectors are typically made from specialized graphite composites, which offer excellent electrical conductivity and heat resistance. Some may also include metal components to enhance durability.

**Q2: How do I determine the right connector size for my application?**

A2: Connector size depends on the current rating and the specific application requirements. Consult manufacturer specifications and guidelines to choose the right size for optimal performance.

**Q3: Can graphite electrode connectors be used in outdoor applications?**

A3: Yes, they can be used outdoors, but additional protective measures should be considered to shield them from environmental factors such as moisture and extreme temperatures.

**Q4: What are the signs of a failing graphite electrode connector?**

A4: Common signs include overheating, discolored materials, visible wear or corrosion, and unexpected system performance issues. Regular inspections can help identify these problems early.

**Q5: How do graphite electrode connectors compare to other types of connectors?**

A5: Graphite electrode connectors excel in high-temperature and high-current applications, while other connectors may be better suited for lower power or less demanding environments. The choice depends on specific operational needs.

9. Conclusion

Choosing the right connector is crucial for ensuring the efficiency and reliability of electrical systems, particularly when it comes to graphite electrode connectors. These specialized connectors play an essential role in various applications, particularly in high-temperature and high-performance environments. By understanding the key characteristics, applications, and selection criteria for graphite electrode connectors, professionals can make informed decisions that enhance system performance and longevity. Prioritizing quality in connectors not only ensures safety but also optimizes the overall functionality of electrical systems, paving the way for successful operations in demanding industrial landscapes.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property