Graphite Electrodes: Pioneering Pollution Control in the Metallurgical Industry

Summary:

Graphite Electrodes and Their Role in Pollution Control

Table of Contents

1. Introduction to Graphite Electrodes

2. Understanding the Metallurgical Industry

2.1 The Production Process

2.2 Common Pollutants in Metallurgy

3. Functionality of Graphite Electrodes

3.1 Composition and Characteristics

3.2 Types of Graphite Electrodes

4. Role of Graphite Electrodes in Pollution Control

4

Graphite Electrodes and Their Role in Pollution Control

Table of Contents

1. Introduction to Graphite Electrodes

2. Understanding the Metallurgical Industry

2.1 The Production Process

2.2 Common Pollutants in Metallurgy

3. Functionality of Graphite Electrodes

3.1 Composition and Characteristics

3.2 Types of Graphite Electrodes

4. Role of Graphite Electrodes in Pollution Control

4.1 Reducing Greenhouse Gas Emissions

4.2 Minimizing Solid Waste Generation

5. Advantages of Using Graphite Electrodes

5.1 Cost-Effectiveness

5.2 Enhanced Energy Efficiency

6. Challenges and Limitations

7. Future Trends in Graphite Electrodes and Pollution Control

7.1 Innovations in Manufacturing

7.2 Regulatory Changes

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Graphite Electrodes

Graphite electrodes serve as crucial components in various industrial processes, particularly in the metallurgical sector. These electrodes are designed to conduct electricity in electric arc furnaces, facilitating the melting of metals. As industries become increasingly aware of their environmental footprint, the role of graphite electrodes in pollution control has gained prominence. This article delves into the multifaceted roles of graphite electrodes and their effectiveness in minimizing environmental damage.

2. Understanding the Metallurgical Industry

The metallurgical industry encompasses the production and processing of metals, a process often associated with significant environmental challenges. Understanding these challenges is essential to appreciating the contributions of graphite electrodes.

2.1 The Production Process

Metallurgical processes involve several stages, including extraction, refining, and alloying. These stages require substantial energy inputs and frequently result in harmful emissions if not managed properly. Electric arc furnaces (EAFs) are increasingly used in this sector due to their efficiency and reduced pollution levels compared to traditional methods.

2.2 Common Pollutants in Metallurgy

The metallurgical industry is responsible for a variety of pollutants, including carbon dioxide (CO2), nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter. These emissions pose serious health and environmental risks, necessitating effective pollution control measures.

3. Functionality of Graphite Electrodes

Graphite electrodes are pivotal in the operation of electric arc furnaces. They not only facilitate the melting of metals but also influence the overall environmental impact of the process.

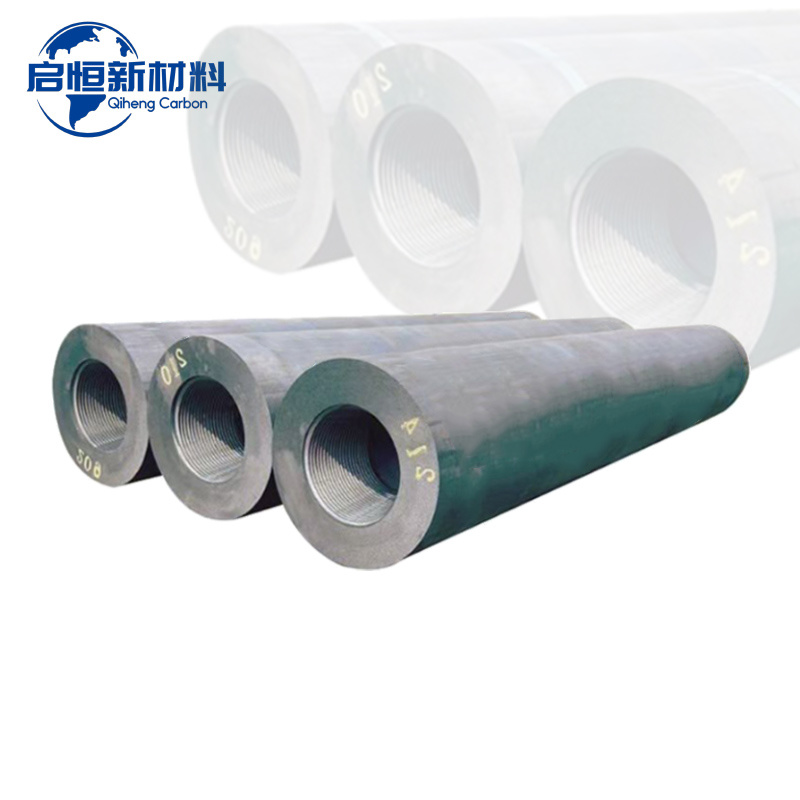

3.1 Composition and Characteristics

Graphite electrodes are primarily composed of high-purity graphite, which is known for its excellent electrical conductivity and thermal resistance. These properties make them ideal for high-temperature applications in metallurgical processes.

3.2 Types of Graphite Electrodes

There are several types of graphite electrodes, classified based on their diameter and density. The most common categories include:

- **Regular Power Electrodes:** Standard electrodes used for conventional applications.

- **High Power Electrodes:** Designed for operations requiring higher electrical power.

- **Ultra High Power Electrodes:** These are utilized in the most demanding applications, offering superior heat and electrical conductivity.

4. Role of Graphite Electrodes in Pollution Control

Graphite electrodes play a significant role in reducing pollution in the metallurgical industry. Their contribution can be seen in various aspects of the manufacturing process.

4.1 Reducing Greenhouse Gas Emissions

By utilizing electric arc furnaces powered by graphite electrodes, industries can significantly cut down on greenhouse gas emissions. EAFs are generally more efficient than traditional blast furnaces, leading to a reduction in CO2 emissions.

4.2 Minimizing Solid Waste Generation

Graphite electrodes also aid in minimizing solid waste generation. Their effective operation allows for the recycling of metals, which reduces the need for raw material extraction and lowers associated environmental impacts.

5. Advantages of Using Graphite Electrodes

The incorporation of graphite electrodes in metallurgical processes offers numerous advantages that contribute to both operational efficiency and environmental sustainability.

5.1 Cost-Effectiveness

While the initial investment in graphite electrodes may be higher than other materials, their durability and efficiency lead to long-term cost savings. Industries benefit from lower electricity consumption and reduced maintenance costs.

5.2 Enhanced Energy Efficiency

Graphite electrodes enable higher energy efficiency in electric arc furnaces. This efficiency is crucial for minimizing operational costs and reducing the overall environmental footprint of metallurgical processes.

6. Challenges and Limitations

Despite their benefits, the use of graphite electrodes is not without challenges. These include the sourcing of high-quality graphite, fluctuating prices, and the need for consistent performance under extreme conditions. Addressing these challenges is essential for the continued viability of graphite electrodes in pollution control.

7. Future Trends in Graphite Electrodes and Pollution Control

As the metallurgical industry evolves, so do the technologies and strategies associated with graphite electrodes.

7.1 Innovations in Manufacturing

Advancements in manufacturing processes are expected to improve the quality and performance of graphite electrodes. Innovations such as enhanced purification techniques will contribute to better conductivity and durability.

7.2 Regulatory Changes

With increasing environmental regulations, industries are likely to invest more in pollution control technologies, including the use of graphite electrodes. Compliance with stricter regulations will drive demand for efficient and sustainable metallurgical practices.

8. Frequently Asked Questions (FAQs)

**Q1: What are graphite electrodes used for?**

Graphite electrodes are primarily used in electric arc furnaces for melting and refining metals.

**Q2: How do graphite electrodes help in pollution control?**

They reduce greenhouse gas emissions and minimize solid waste generation by improving energy efficiency and enabling metal recycling.

**Q3: Are graphite electrodes cost-effective?**

While they may have a higher upfront cost, their durability and efficiency often lead to long-term cost savings.

**Q4: What types of graphite electrodes exist?**

Common types include regular power, high power, and ultra-high power electrodes, suited for different applications.

**Q5: What challenges do graphite electrodes face?**

Challenges include sourcing high-quality graphite, fluctuating prices, and maintaining performance under extreme conditions.

9. Conclusion

Graphite electrodes are essential components in the metallurgical industry, playing a vital role in pollution control. Their ability to enhance energy efficiency and reduce harmful emissions positions them as a cornerstone for sustainable practices in metal production. As innovations continue and regulatory pressures increase, the importance of graphite electrodes will only grow, making them a key player in the future of the metallurgy sector. By embracing these technologies, we can aspire to achieve a cleaner, more efficient industry that prioritizes environmental health alongside economic viability.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property