Unlocking the Potential of Petroleum Coke in Modern Industry

Summary:

Unlocking the Potential of Petroleum Coke in Modern Industry

Table of Contents

1. Introduction to Petroleum Coke

2. The Composition and Properties of Petroleum Coke

3. Applications of Petroleum Coke in Various Industries

3.1 Use in Aluminum Production

3.2 Role in Cement Manufacturing

3.3 Contribution to Energy Generation

4. Environmental Considerations of Petroleum Coke

5. Future T

Unlocking the Potential of Petroleum Coke in Modern Industry

Table of Contents

1. Introduction to Petroleum Coke

2. The Composition and Properties of Petroleum Coke

3. Applications of Petroleum Coke in Various Industries

3.1 Use in Aluminum Production

3.2 Role in Cement Manufacturing

3.3 Contribution to Energy Generation

4. Environmental Considerations of Petroleum Coke

5. Future Trends: Innovations in Petroleum Coke Usage

6. Frequently Asked Questions (FAQs)

7. Conclusion

1. Introduction to Petroleum Coke

Petroleum coke, commonly referred to as petcoke, is a carbon-rich solid derived from oil refining. It emerges as a byproduct during the coking process, where heavy oil fractions are thermally decomposed. With its increasing significance in modern industry, understanding its properties, applications, and environmental implications is vital for stakeholders across various sectors.

2. The Composition and Properties of Petroleum Coke

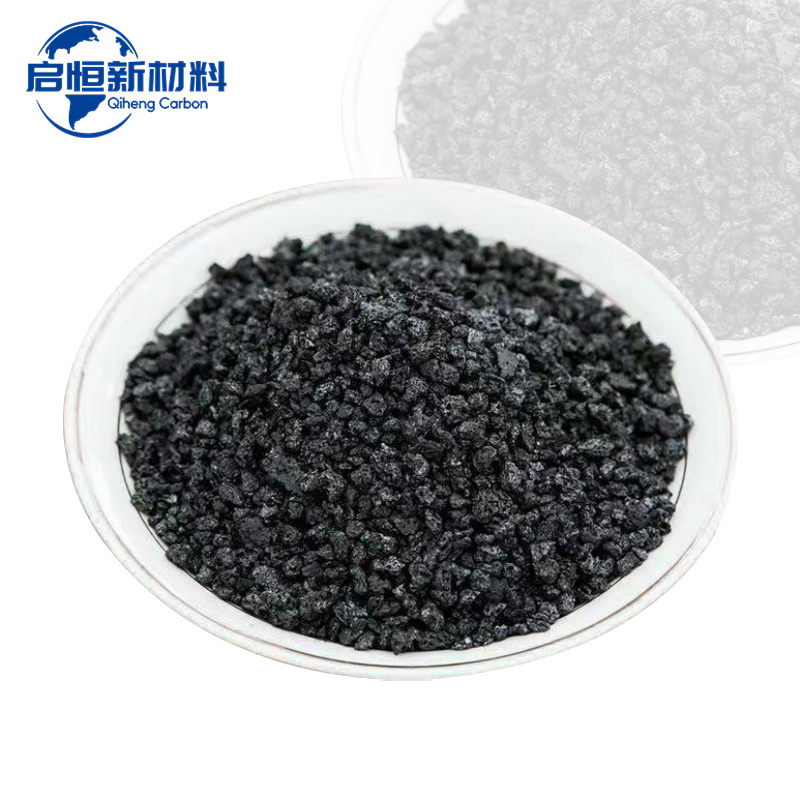

Petroleum coke primarily consists of carbon (over 80%), along with various impurities such as sulfur, hydrogen, and nitrogen. The properties of petcoke can vary based on the type of crude oil used and the refining processes involved. Two main types are produced: **green petroleum coke**, which is unprocessed and contains higher levels of volatile matter, and **calcined petroleum coke**, which undergoes heating to remove impurities and increase carbon content.

The unique properties of petroleum coke, including its high calorific value and low ash content, make it an attractive alternative fuel source. Furthermore, its physical structure contributes to its conductivity, making it useful in various applications beyond energy production.

3. Applications of Petroleum Coke in Various Industries

Petroleum coke's versatility enables its use across multiple industries. Here are some of the critical areas where petcoke plays a pivotal role:

3.1 Use in Aluminum Production

The aluminum industry heavily relies on calcined petroleum coke for the production of aluminum metal. The high carbon content and low ash levels of calcined petcoke make it an ideal anode material in the Hall-Héroult process of aluminum electrolysis.

This process requires large amounts of energy, and the use of petcoke as an anode minimizes costs and enhances efficiency. With the global demand for aluminum on the rise, the dependence on petcoke in this sector is projected to increase significantly.

3.2 Role in Cement Manufacturing

In the cement industry, petroleum coke serves as a valuable alternative fuel. Its high calorific value allows it to be used to replace coal in the cement manufacturing process, helping to reduce costs and emissions. The use of petcoke not only supports energy efficiency but also contributes to the overall sustainability of the cement production process.

Moreover, integrating petcoke into the cement production process can aid in achieving regulatory compliance regarding greenhouse gas emissions, making it a preferred choice for environmentally conscious companies.

3.3 Contribution to Energy Generation

Petroleum coke is increasingly being used as a fuel for power generation. Power plants are beginning to blend petcoke with coal or use it as a standalone fuel source. As a high-energy fuel, petcoke can contribute to improved energy output while maintaining competitive costs.

Furthermore, with the global shift towards reducing carbon footprints, the use of petroleum coke in energy generation may provide a transitional solution as industries work towards cleaner alternatives.

4. Environmental Considerations of Petroleum Coke

The use of petroleum coke does not come without its environmental challenges. While petcoke offers advantages in cost and energy output, it also raises concerns regarding emissions. Burning petcoke can release significant amounts of sulfur dioxide (SO2) and particulate matter into the atmosphere, contributing to air pollution.

To mitigate these effects, it is crucial for industries to adopt advanced emissions control technologies and implement best practices in managing petcoke usage. Regulations and standards are continually evolving, prompting stakeholders to seek innovative solutions that balance economic benefits with environmental stewardship.

5. Future Trends: Innovations in Petroleum Coke Usage

As industries evolve, so too does the potential for petroleum coke to play an integral role in sustainable practices. Research and innovation are driving the development of new technologies to enhance the efficiency of petcoke utilization. This includes:

- **Carbon Capture and Storage (CCS)**: Implementing CCS technologies can significantly reduce the carbon emissions associated with burning petcoke, making it a more environmentally friendly fuel option.

- **Alternative Pathways**: Ongoing studies are exploring the conversion of petcoke into higher-value products, such as chemicals and advanced materials, which could diversify its application and reduce waste.

- **Circular Economy Initiatives**: Emphasizing recycling and reusing petcoke waste can lead to more sustainable practices, reducing the reliance on virgin materials and minimizing environmental impacts.

6. Frequently Asked Questions (FAQs)

What is petroleum coke used for?

Petroleum coke is used primarily in aluminum production, cement manufacturing, and energy generation. Its high carbon content and calorific value make it ideal for these applications.

Is petroleum coke environmentally friendly?

While petroleum coke offers economic benefits, it poses environmental challenges due to emissions when burned. However, advancements in technology are being developed to minimize these impacts.

How is petroleum coke produced?

Petroleum coke is produced as a byproduct of the coking process in oil refining, where heavy oil fractions are thermally decomposed.

Can petroleum coke be used as an alternative fuel?

Yes, petroleum coke can be used as an alternative fuel source in various industries, particularly in cement manufacturing and power generation.

What are the advantages of using petroleum coke in aluminum production?

The primary advantages include cost efficiency, reduced emissions, and enhanced energy efficiency due to its high carbon content and low ash levels.

7. Conclusion

In conclusion, petroleum coke stands as a crucial component in the modern industrial landscape, offering diverse applications and benefits across multiple sectors. As industries seek ways to balance economic viability with environmental responsibility, the innovative use of petcoke presents remarkable possibilities. By embracing advanced technologies and sustainable practices, we can unlock the full potential of petroleum coke, paving the way for a more efficient and responsible industrial future. The ongoing exploration into its applications and environmental impact will undoubtedly shape the trajectory of this resource in the years to come.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property