Common Myths About Graphite Electrodes Debunked: Unveiling the Truth Behind Their Use and Performance

Summary:

Introduction

In the realm of metallurgy and energy, **graphite electrodes** play an indispensable role, particularly in electric arc furnaces (EAF) used for steelmaking. Despite their importance, a myriad of myths and misconceptions surrounds these components, leading to misunderstandings that can affect decision-making in industrial applications. This article aims to debunk prevalent myths about

Introduction

In the realm of metallurgy and energy, **graphite electrodes** play an indispensable role, particularly in electric arc furnaces (EAF) used for steelmaking. Despite their importance, a myriad of myths and misconceptions surrounds these components, leading to misunderstandings that can affect decision-making in industrial applications. This article aims to debunk prevalent myths about graphite electrodes, providing factual insights into their functions, benefits, and limitations.

Understanding Graphite Electrodes

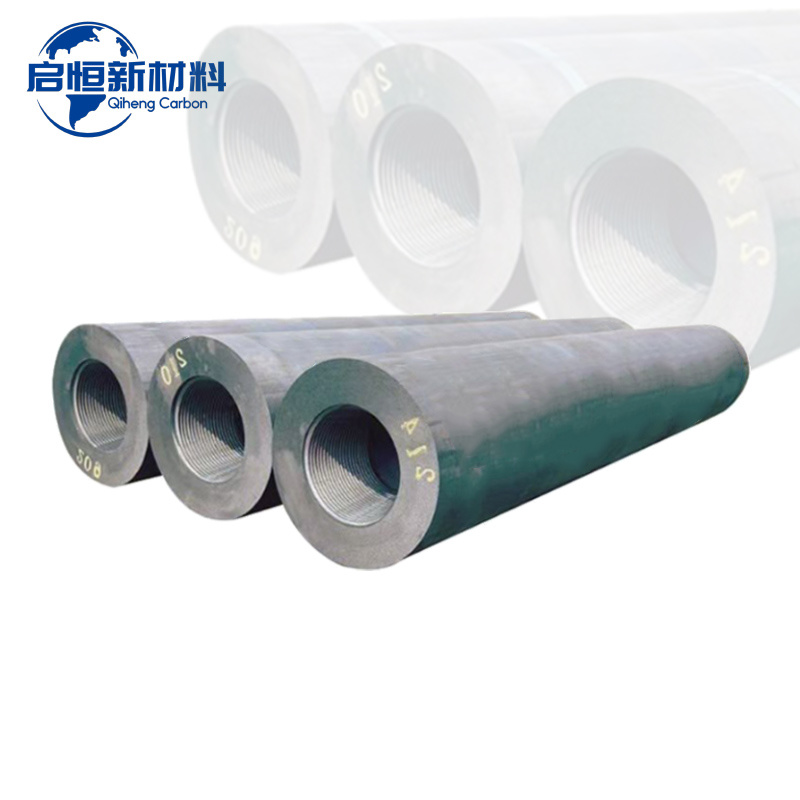

Graphite electrodes are made from high-quality petroleum coke and pitch, which undergo a series of processes to create the desired characteristics for industrial use. These electrodes facilitate the conduction of electricity in electric arc furnaces, where they produce the heat necessary for transforming scrap metal into steel.

The Role of Graphite Electrodes in Electric Arc Furnaces

Electric arc furnaces rely on graphite electrodes to create an electric arc between the electrodes and the steel scrap. This arc generates intense heat, producing temperatures exceeding 3,000 degrees Celsius. This process allows for the melting of scrap metal, which can be recycled into new steel. The efficiency and effectiveness of this melting process are often attributed to the quality of the electrodes used.

Myth 1: All Graphite Electrodes Are the Same

One significant misconception is that all graphite electrodes are interchangeable. In reality, different grades of graphite electrodes exist, each tailored for specific applications. Factors such as electrical conductivity, thermal conductivity, and mechanical strength can vary significantly between grades.

Understanding Different Grades of Graphite Electrodes

The choice of electrode grade is crucial for optimizing performance in EAF operations. High-quality electrodes can enhance energy efficiency, reduce wear, and improve overall melting rates. Conversely, using lower-grade electrodes can lead to increased power consumption and operational inefficiencies.

Myth 2: Graphite Electrodes Are Not Environmentally Friendly

Another common myth is that graphite electrodes contribute significantly to environmental degradation. While it is true that the production of graphite electrodes involves certain emissions, advancements in technology have led to more sustainable manufacturing processes.

Eco-Friendly Innovations in Graphite Electrode Production

Modern manufacturing techniques focus on minimizing waste and emissions associated with the production of graphite electrodes. Additionally, the recycling of scrap metals in EAFs helps reduce the carbon footprint. Many manufacturers are also adopting practices that align with global sustainability goals, further underscoring the eco-friendly nature of using recycled materials in steel production.

Myth 3: Graphite Electrodes Have a Short Lifespan

The perception that graphite electrodes wear out quickly is another myth that requires clarification. The lifespan of these electrodes can vary based on several factors, including the specific application, operational conditions, and the quality of the electrodes themselves.

Factors Influencing the Lifespan of Graphite Electrodes

Several elements can affect the longevity of graphite electrodes:

- **Quality of Raw Materials**: Higher-grade raw materials lead to better-quality electrodes.

- **Operational Practices**: Proper monitoring and control during the melting process can extend the life of electrodes.

- **Cooling Systems**: Effective cooling systems reduce thermal stress, prolonging electrode lifespan.

By understanding these factors, operators can implement strategies to maximize the life of graphite electrodes, ultimately saving costs and improving efficiency.

Myth 4: Graphite Electrodes Are Costly and Not Worth the Investment

Many believe that investing in high-quality graphite electrodes is not financially feasible for their operations. However, this viewpoint overlooks the long-term benefits that quality electrodes provide.

Cost-Benefit Analysis of High-Quality Graphite Electrodes

While the upfront cost of high-quality graphite electrodes may be greater, the long-term savings in energy consumption, reduced downtime, and increased melting efficiency can offset initial expenditures. Businesses that prioritize quality often experience fewer interruptions in production, leading to greater profitability in the long run.

Myth 5: Graphite Electrodes Are Only Useful for Steelmaking

The assumption that graphite electrodes have limited applications primarily in steelmaking is misleading. These versatile components find utility in several other industrial processes.

Other Applications of Graphite Electrodes

Beyond steelmaking, graphite electrodes are used in:

- **Aluminum Production**: They play a critical role in the melting and refining processes.

- **Foundries**: Graphite electrodes are essential for producing cast iron and other alloys.

- **Chemical Industries**: They are involved in producing silicon metal and other chemical processes.

The diverse applications of graphite electrodes highlight their essential role in industrial practices beyond steel production.

Myth 6: Using Graphite Electrodes Is a Dying Industry

With the rise of alternative technologies, some might assume that the use of graphite electrodes is waning. However, this assertion fails to recognize the evolving landscape of the metallurgy and energy sectors.

The Future of Graphite Electrodes in Modern Industry

Despite advancements in technology, the demand for steel remains high, and with it, the need for efficient melting processes continues to grow. The versatility, efficiency, and cost-effectiveness of graphite electrodes ensure their sustained relevance in the metallurgy industry. Moreover, ongoing research and development aim to enhance the performance characteristics of graphite electrodes, reinforcing their position in modern manufacturing.

Myth 7: Graphite Electrodes Are Difficult to Handle and Install

Some individuals believe that graphite electrodes are cumbersome and challenging to manage. In reality, advancements in electrode design and handling equipment have simplified the handling and installation processes.

Innovations in Handling and Installation of Graphite Electrodes

Modern graphite electrodes come with features that facilitate easier handling, such as:

- **Modular Designs**: Many electrodes are designed in shorter lengths, making them easier to transport and install.

- **Advanced Cranes and Lifters**: Specialized equipment exists to aid in the quick and safe installation of electrodes in electric arc furnaces.

These innovations contribute to a more streamlined installation process, minimizing potential downtime during electrode replacements.

Conclusion

Understanding the truth behind common myths about graphite electrodes is crucial for industry professionals. By debunking these misconceptions, we can appreciate the significant role that graphite electrodes play in modern metallurgy and energy applications. From their diverse applications to their importance in steel production, graphite electrodes are not only vital to the industry but also continuing to evolve with technological advancements. Embracing accurate information allows businesses to make informed decisions, optimizing productivity and efficiency in their operations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property