Graphite Electrodes: Optimizing Your Production Efficiency for Maximum Output

Summary:

Graphite Electrodes: Optimizing Your Production Efficiency for Maximum Output

Table of Contents

Introduction to Graphite Electrodes and Their Importance

Understanding Graphite: Properties and Applications

The Graphite Electrode Production Process

Key Factors Influencing Production Efficiency

Techniques for Optimizing Production Efficiency

Reducing Costs While Maintaining Q

Graphite Electrodes: Optimizing Your Production Efficiency for Maximum Output

Table of Contents

- Introduction to Graphite Electrodes and Their Importance

- Understanding Graphite: Properties and Applications

- The Graphite Electrode Production Process

- Key Factors Influencing Production Efficiency

- Techniques for Optimizing Production Efficiency

- Reducing Costs While Maintaining Quality

- Future Trends in Graphite Electrode Production

- Frequently Asked Questions (FAQs)

- Conclusion

Introduction to Graphite Electrodes and Their Importance

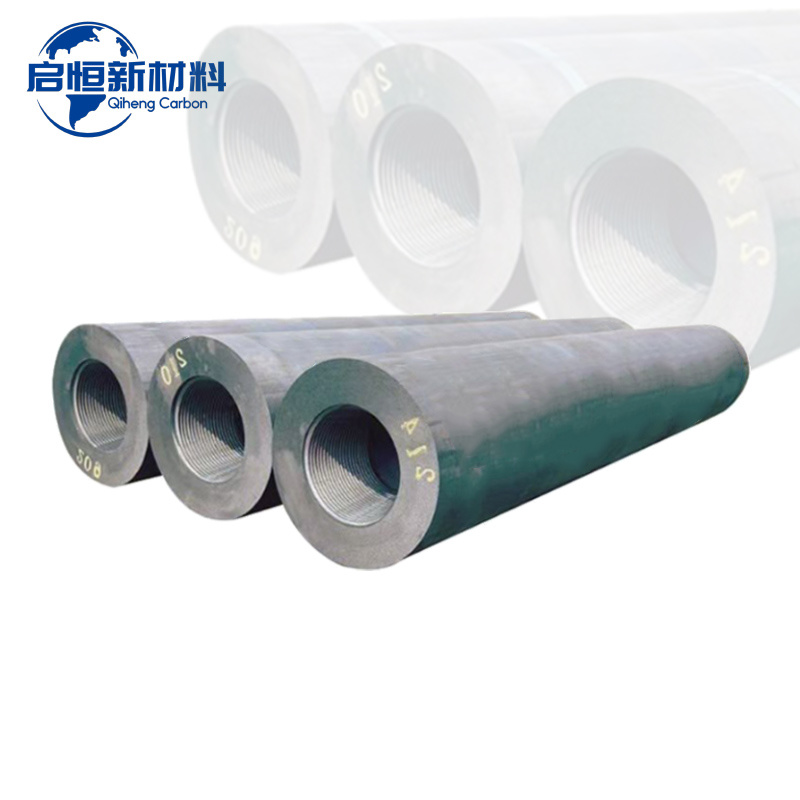

In the realm of metallurgy, **graphite electrodes** play a pivotal role in the production of steel and other metals. These high-performance electrodes are essential for electric arc furnaces (EAFs) and ladle furnaces, where they facilitate the melting process of scrap metal. As industries push for higher efficiency and lower operational costs, the optimization of graphite electrode production has become increasingly critical.

This article will explore how we can enhance production efficiency through various methods and techniques, ultimately leading to cost reduction and improved output quality.

Understanding Graphite: Properties and Applications

Graphite is a naturally occurring form of carbon characterized by its excellent electrical conductivity, thermal resistance, and chemical inertness. These properties make graphite an ideal material for electrodes used in high-temperature applications, particularly in the metallurgy sector.

### H3>The Unique Properties of Graphite

The unique properties of graphite include:

- **High Thermal Conductivity**: Graphite can withstand extreme temperatures, making it suitable for high-temperature applications.

- **Electrical Conductivity**: Its ability to conduct electricity efficiently is crucial for electric arc furnaces.

- **Chemical Stability**: Graphite is resistant to most chemical reactions, ensuring durability and longevity.

### H3>Applications of Graphite Electrodes

Graphite electrodes are primarily utilized in:

- **Electric Arc Furnaces (EAFs)**: For melting scrap metal.

- **Ladle Furnaces**: For refining steel and other alloys.

- **Non-Ferrous Industries**: Such as aluminum production and copper smelting.

The Graphite Electrode Production Process

The production of graphite electrodes involves several intricate steps, each of which must be meticulously controlled to maintain quality and efficiency. The process generally includes:

1. **Raw Material Selection**: High-quality petroleum coke and pitch are selected as the primary raw materials.

2. **Mixing and Forming**: The raw materials are mixed and shaped into blanks.

3. **Baking**: The formed blanks are baked at high temperatures to convert them into carbonized products.

4. **Graphitization**: The carbonized products are then subjected to extremely high temperatures (above 2500°C) to achieve a graphitized structure.

5. **Machining**: Finally, the electrodes are machined to specific dimensions and quality specifications.

### H3>Quality Control During Production

Implementing stringent quality control measures at each stage of production is essential. This includes monitoring raw material quality, testing electrode properties, and ensuring precise machining.

Key Factors Influencing Production Efficiency

Several factors can significantly influence the production efficiency of graphite electrodes:

### H3>1. Raw Material Quality

The quality of petroleum coke and pitch has a direct impact on the final product's performance. Using high-purity materials minimizes defects and enhances the electrodes' properties.

### H3>2. Temperature Control

Maintaining optimal temperatures during the baking and graphitization stages is critical. Deviations can lead to inconsistent quality and increased production times.

### H3>3. Equipment Maintenance

Regular maintenance of production equipment ensures continuous operation and prevents unplanned downtimes, thus improving efficiency.

### H3>4. Skilled Workforce

Having a well-trained workforce is vital for operating machinery efficiently and adhering to quality control protocols.

Techniques for Optimizing Production Efficiency

To enhance production efficiency, several strategies can be implemented:

### H3>1. Automation and Technology Integration

Incorporating automation technologies can streamline various aspects of the production process. Automated systems help in monitoring temperature, controlling raw material feeding, and managing quality checks.

### H3>2. Process Optimization

Utilizing process optimization techniques such as Lean Manufacturing and Six Sigma can significantly reduce waste and improve production flow. These methodologies focus on minimizing defects, reducing lead times, and enhancing overall productivity.

### H3>3. Data Analytics and Monitoring

Implementing data analytics tools can provide insights into production metrics, enabling continuous improvement. Real-time monitoring helps identify bottlenecks and inefficiencies, allowing for immediate corrective actions.

### H3>4. Collaboration with Suppliers

Building strong relationships with suppliers ensures a consistent supply of high-quality raw materials. Collaborating on quality standards can lead to improved raw material performance and reduced variation in the final product.

### H3>5. Employee Training and Development

Investing in employee training programs can enhance skill sets and knowledge. This leads to better decision-making on the shop floor and improved adherence to quality standards.

Reducing Costs While Maintaining Quality

Cost reduction is a critical aspect of optimizing production efficiency. However, it should not come at the expense of quality. Here are some strategies to achieve this balance:

### H3>1. Energy Efficiency

Implementing energy-efficient practices can significantly reduce operational costs. Upgrading to energy-efficient equipment and optimizing heating processes can lead to substantial savings.

### H3>2. Recycling and Waste Management

Recycling scrap materials and implementing effective waste management practices can reduce production costs. By reusing by-products, companies can minimize raw material expenses.

### H3>3. Process Simplification

Simplifying production processes can reduce the time and resources required for manufacturing. Identifying and eliminating unnecessary steps can enhance efficiency and lower costs.

### H3>4. Negotiating Supplier Contracts

Regularly reviewing and negotiating supplier contracts can help secure better rates for raw materials, further driving down costs without compromising quality.

Future Trends in Graphite Electrode Production

As the industry evolves, new trends are shaping the future of graphite electrode production:

### H3>1. Sustainable Practices

The push for sustainability is driving innovations in the production process. Companies are exploring eco-friendly materials and energy-efficient technologies to reduce their carbon footprint.

### H3>2. Advanced Materials and Technologies

Research into alternative materials and advanced manufacturing techniques, such as additive manufacturing, is paving the way for more efficient production processes.

### H3>3. Digital Transformation

The integration of artificial intelligence (AI) and machine learning into production systems is enhancing decision-making capabilities and operational efficiencies.

### H3>4. Global Supply Chain Optimization

As companies expand globally, optimizing supply chains will become essential for reducing costs and ensuring timely delivery of raw materials and finished products.

Frequently Asked Questions (FAQs)

### H3>1. What are graphite electrodes used for?

Graphite electrodes are primarily used in electric arc furnaces for melting scrap metal, as well as in ladle furnaces for refining steel and other alloys.

### H3>2. How can production efficiency be measured?

Production efficiency can be measured by assessing output rates, quality control metrics, and overall equipment effectiveness (OEE).

### H3>3. What factors affect the quality of graphite electrodes?

Factors such as raw material quality, temperature control during production, and machining precision significantly affect the quality of graphite electrodes.

### H3>4. Are there any eco-friendly alternatives to graphite electrodes?

Research is ongoing into alternative materials and eco-friendly practices, but graphite electrodes remain the standard due to their unique properties.

### H3>5. How important is employee training in production efficiency?

Employee training is crucial as it enhances skill sets, leads to better quality control, and fosters a culture of continuous improvement on the manufacturing floor.

Conclusion

Optimizing the production efficiency of graphite electrodes is vital in today’s competitive landscape. By understanding the production process, implementing advanced techniques, and maintaining a focus on quality, we can enhance productivity while reducing costs. The future of graphite electrode manufacturing holds exciting possibilities, especially as we embrace sustainable practices and technological advancements. Companies that adapt to these trends will likely lead the industry in efficiency, quality, and profitability.

Previous:

Focus On Hot Spots

Graphite Electrodes: Optimizing Your Production Efficiency for Maximum Output

Graphite Electrodes: Optimizing Your Production Efficiency for Maximum Output

Table of Contents

Introduction to Graphite Electrodes and Their Importance

Understanding Graphite: Properties and Applications

The Graphite Electrode Production Process

Key Factors Influencing Production Efficiency

Techniques for Optimizing Production Efficiency

Reducing Costs While Maintaining Q

Understanding Graphite Electrode Carbon Bricks: Key Concepts and Applications

Graphite electrode carbon bricks are essential materials widely used in various industrial applications, particularly in the metallurgy and energy sectors. These bricks, composed primarily of high-quality graphite, play a critical role in electrical conductivity and thermal stability, making them indispensable in processes like electric arc furnace (EAF) steelmaking.

One of the primary advantages