The Future of Graphite Electrodes in High-Tech Manufacturing: Innovations and Applications

Summary:

The Future of Graphite Electrodes in High-Tech Manufacturing

High-tech manufacturing is undergoing a significant transformation, driven by advancements in materials and technology. Among the pivotal components in this evolution are graphite electrodes, which are essential in various high-temperature applications. With the increasing demand for high-performance materials, the future of graphite ele

The Future of Graphite Electrodes in High-Tech Manufacturing

High-tech manufacturing is undergoing a significant transformation, driven by advancements in materials and technology. Among the pivotal components in this evolution are graphite electrodes, which are essential in various high-temperature applications. With the increasing demand for high-performance materials, the future of graphite electrodes appears promising, especially in sectors such as steel production, battery manufacturing, and semiconductor fabrication. This article explores the advancements, applications, and future trends of graphite electrodes in high-tech manufacturing.

Table of Contents

- 1. Introduction to Graphite Electrodes

- 2. Importance of Graphite Electrodes in Manufacturing

- 3. Key Applications of Graphite Electrodes

- 3.1. Graphite Electrodes in Steel Production

- 3.2. Role in Battery Manufacturing

- 3.3. Use in Semiconductor Fabrication

- 4. Innovations in Graphite Electrode Manufacturing

- 5. Market Trends and Future Outlook

- 6. Challenges Facing the Graphite Electrode Market

- 7. Conclusion

- 8. Frequently Asked Questions (FAQs)

1. Introduction to Graphite Electrodes

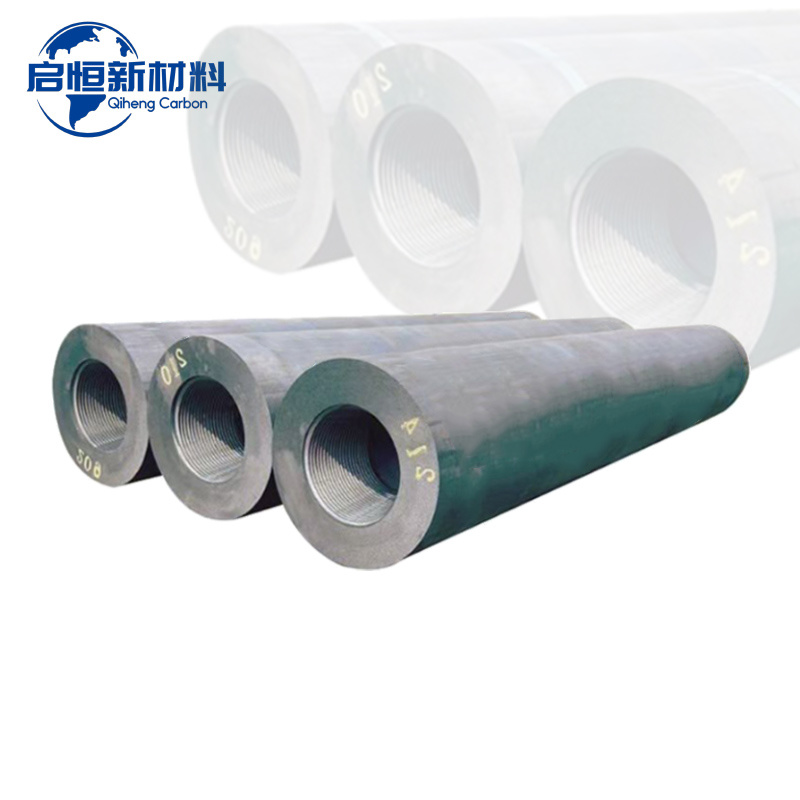

Graphite electrodes are critical components used in high-temperature industrial processes. Made from high-quality petroleum coke and a binder pitch, these electrodes are primarily utilized in electric arc furnaces (EAF) for steel production. The unique properties of graphite, including its exceptional thermal conductivity, high temperature resistance, and chemical stability, make it a preferred choice in various manufacturing applications. As industries evolve, the demand for enhanced performance and efficiency in graphite electrodes continues to grow.

2. Importance of Graphite Electrodes in Manufacturing

The importance of graphite electrodes in manufacturing cannot be overstated. They play a vital role in various processes, including:

- **Electrical Conductivity**: Graphite electrodes provide excellent electrical conductivity, allowing for efficient energy transfer in electric arc furnaces.

- **High-Temperature Resistance**: Capable of withstanding extreme temperatures, graphite electrodes are essential for processes that require high heat, such as steel and aluminum production.

- **Chemical Stability**: The chemical inertness of graphite minimizes contamination risks, ensuring the purity of the final products.

- **Cost-Effectiveness**: Graphite electrodes offer a cost-effective solution for high-performance applications, especially in industries seeking to enhance productivity while managing costs.

3. Key Applications of Graphite Electrodes

Graphite electrodes have a wide range of applications across various high-tech manufacturing sectors. Below, we explore some of the most significant uses.

3.1. Graphite Electrodes in Steel Production

The steel industry is the largest consumer of graphite electrodes. EAFs, which utilize these electrodes for melting scrap steel and producing high-quality steel, rely heavily on the unique properties of graphite. As the demand for steel continues to rise globally, the need for efficient and durable graphite electrodes in the EAF process becomes increasingly crucial. The evolution of steel production methods further supports this trend, as manufacturers seek to adopt more sustainable and efficient practices.

3.2. Role in Battery Manufacturing

Graphite electrodes play an essential role in battery manufacturing, particularly in lithium-ion batteries, which are widely used in electric vehicles (EVs) and consumer electronics. The performance of these batteries heavily relies on the quality and purity of the graphite used in their anodes. As the demand for EVs rises, so will the need for high-quality graphite electrodes capable of delivering superior electrical performance and energy density.

3.3. Use in Semiconductor Fabrication

In the semiconductor industry, graphite electrodes are used in various stages of the manufacturing process, including the production of silicon wafers. The unique properties of graphite, including its thermal stability and conductivity, make it ideal for creating high-quality semiconductor devices. With the growing demand for advanced electronics and smart devices, the use of graphite electrodes in semiconductor fabrication is set to expand significantly.

4. Innovations in Graphite Electrode Manufacturing

The graphite electrode industry is witnessing several innovative developments aimed at improving performance and sustainability. These innovations are critical for meeting the evolving demands of high-tech manufacturing.

4.1. Advanced Materials and Technologies

Advancements in materials science have led to the development of new formulations and manufacturing techniques for graphite electrodes. These innovations aim to enhance electrical conductivity, thermal resistance, and overall performance. Researchers are exploring alternatives to traditional petroleum-based materials, focusing on renewable sources and environmentally friendly processes.

4.2. Sustainability in Graphite Production

Sustainability is a growing concern in the graphite electrode industry. Manufacturers are increasingly adopting greener practices, including recycling graphite waste and developing processes to minimize carbon emissions. These efforts not only reduce the environmental impact of graphite production but also align with the global push toward sustainable manufacturing.

5. Market Trends and Future Outlook

The graphite electrode market is poised for significant growth in the coming years. According to industry forecasts, the global market for graphite electrodes is projected to expand as demand increases across various sectors. Key drivers of this growth include:

- **Rising Steel Production**: As developing economies continue to industrialize, the demand for steel is expected to increase, driving the need for graphite electrodes.

- **Growth of Electric Vehicles**: The surge in EV production is creating a substantial demand for high-quality graphite anodes in batteries.

- **Technological Advancements**: Ongoing innovations in materials and manufacturing processes are enhancing the performance and efficiency of graphite electrodes.

6. Challenges Facing the Graphite Electrode Market

While the future looks promising for graphite electrodes, several challenges must be addressed:

- **Volatility in Raw Material Prices**: Fluctuations in the prices of raw materials, such as petroleum coke, can impact the profitability of graphite electrode manufacturers.

- **Environmental Regulations**: Stricter environmental regulations may require manufacturers to adopt more sustainable practices, which could increase production costs.

- **Competition from Alternative Materials**: Emerging materials, such as copper and silicon-based electrodes, present competition to traditional graphite electrodes, necessitating continuous innovation and adaptation.

7. Conclusion

In conclusion, graphite electrodes are poised to play a crucial role in the future of high-tech manufacturing. Their unique properties make them indispensable in various industries, including steel production, battery manufacturing, and semiconductor fabrication. As advancements in materials and manufacturing processes continue to evolve, the graphite electrode market is expected to witness substantial growth. By addressing the challenges and embracing innovations, manufacturers can ensure that graphite electrodes remain central to the future of high-tech manufacturing.

8. Frequently Asked Questions (FAQs)

1. What are graphite electrodes used for?

Graphite electrodes are primarily used in electric arc furnaces for steel production, as well as in battery manufacturing and semiconductor fabrication.

2. Why are graphite electrodes important in electric arc furnaces?

Their excellent electrical conductivity, high-temperature resistance, and chemical stability make graphite electrodes essential for efficient energy transfer in electric arc furnaces.

3. How are graphite electrodes manufactured?

Graphite electrodes are made from high-quality petroleum coke and binder pitch, which are processed through methods such as molding and graphitization.

4. What are the environmental impacts of graphite production?

Graphite production can have environmental impacts, including carbon emissions and resource depletion. However, many manufacturers are adopting sustainable practices to minimize these effects.

5. What is the future outlook for the graphite electrode industry?

The future of the graphite electrode industry looks promising, driven by increasing demand across various sectors and ongoing innovations in materials and manufacturing processes.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property