What Makes Petroleum Coke Essential for Aluminum Production?

Summary:

What Makes Petroleum Coke Essential for Aluminum Production?

Introduction to Petroleum Coke and Its Role in Aluminum Production

Petroleum coke, commonly referred to as petcoke, is a carbonaceous solid derived from the oil refining process. It plays a **vital role** in various industrial applications, particularly in aluminum production. In the aluminum manufacturing sector, petcoke is mainly used

What Makes Petroleum Coke Essential for Aluminum Production?

Introduction to Petroleum Coke and Its Role in Aluminum Production

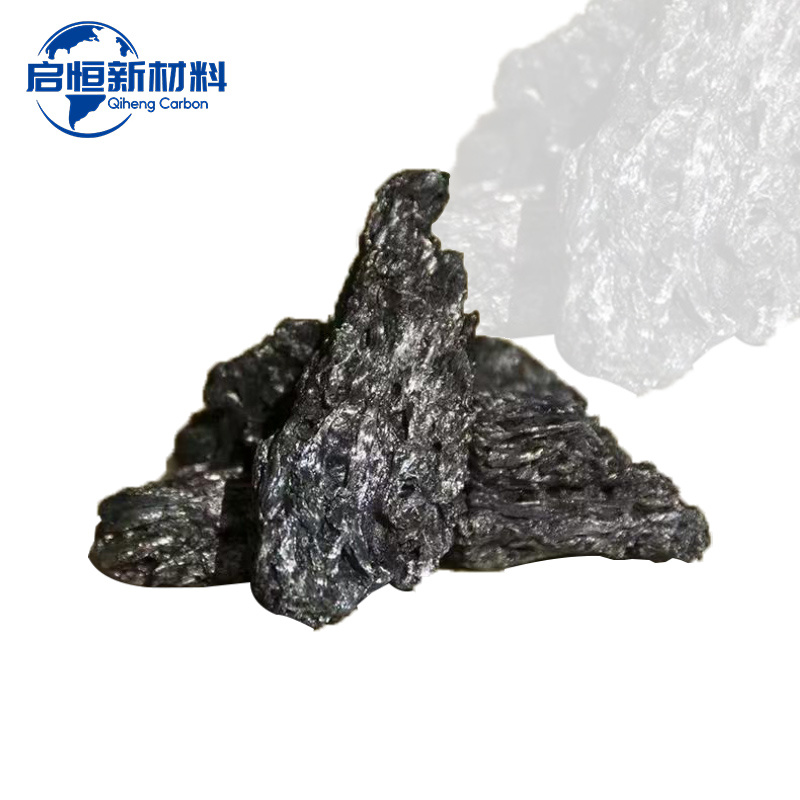

Petroleum coke, commonly referred to as petcoke, is a carbonaceous solid derived from the oil refining process. It plays a **vital role** in various industrial applications, particularly in aluminum production. In the aluminum manufacturing sector, petcoke is mainly used as a **key component** in the production of anodes, which are essential for the electrolytic reduction of aluminum oxide into aluminum metal. Understanding its significance requires a comprehensive look at the production processes, characteristics, and advantages of using petroleum coke.

Understanding Petroleum Coke: Definition and Properties

Defining Petroleum Coke

Petroleum coke is produced during the **coking process**, where heavy hydrocarbons in crude oil are thermally decomposed. The final product is a dense, solid carbon material that possesses high carbon content and several desirable properties for industrial applications.

Properties of Petroleum Coke

- **High Carbon Content:** Petcoke typically contains over 80% carbon, making it an efficient source of carbon for aluminum anodes.

- **Low Sulfur Levels:** The sulfur content in petcoke is generally low, which is crucial for minimizing pollution during aluminum production.

- **Excellent Thermal Stability:** Petroleum coke can withstand high temperatures, which is essential for its use in aluminum smelting processes.

- **Porosity and Particle Size:** Its porous structure and variable particle size can be tailored to meet specific production requirements.

The Importance of Petroleum Coke in Aluminum Production

How Petroleum Coke is Used in Anode Production

In the aluminum production process, petroleum coke is primarily used to manufacture **carbon anodes**. These anodes serve as the conductive element in electrolytic cells, allowing electrical currents to pass through and facilitating the electrolysis of aluminum oxide (Al2O3). The efficiency and quality of the aluminum produced heavily depend on the quality of these anodes.

Advantages of Using Petroleum Coke

1. **Cost-Effectiveness:** Petcoke is generally less expensive than other carbon sources like coal or graphite, making it a preferred choice in aluminum production.

2. **Enhanced Electrical Conductivity:** The high carbon content of petcoke leads to superior electrical conductivity compared to other materials, improving the efficiency of the electrolytic process.

3. **Reduced Environmental Impact:** The use of low-sulfur petcoke minimizes sulfur dioxide emissions during the aluminum smelting process, contributing to a greener production method.

4. **Improved Anode Quality:** The properties of petcoke contribute to the strength and longevity of the anodes, which can translate to lower costs and increased productivity in aluminum plants.

The Manufacturing Process of Aluminum Anodes Using Petroleum Coke

Step-by-Step Anode Production

The anode production process involves several key steps:

1. **Material Preparation:** The raw materials, including petroleum coke and pitch (a binder), are crushed and mixed to achieve the desired consistency.

2. **Molding:** The mixture is then molded into the shape of anodes, which are typically rectangular blocks.

3. **Baking:** The molded anodes are baked in large ovens at high temperatures, which hardens the material and enhances its structural integrity.

4. **Electrolysis:** Once the anodes are produced, they are used in the electrolytic reduction process to extract aluminum from its ore.

Quality Control in Anode Production

To ensure the quality of the anodes, various tests are conducted throughout the production process. These tests assess the carbon content, density, and electrical conductivity of the anodes, ensuring they meet stringent industry standards.

The Future of Petroleum Coke in Aluminum Production

Innovations and Sustainable Practices

As the aluminum industry evolves, there is an increasing focus on sustainability and reducing environmental impact. Some emerging trends include:

- **Recycling Petcoke:** Initiatives are being developed to recycle petroleum coke waste, thus minimizing the environmental footprint of aluminum production.

- **Alternative Feedstocks:** Research is ongoing to explore alternative carbon sources that maintain performance while offering lower environmental impacts.

- **Carbon Capture Technologies:** Innovative technologies aimed at capturing carbon emissions during the aluminum production process are being integrated, further enhancing sustainability.

Challenges and Considerations in Using Petroleum Coke

Environmental Concerns

Despite the advantages, the use of petroleum coke in aluminum production is not without challenges. The environmental concerns associated with its production and usage need to be addressed, including:

- **Air Pollution:** Emissions from petcoke combustion can contribute to air pollution if not properly managed.

- **Waste Management:** The disposal of residual petcoke poses a challenge, necessitating sustainable waste management practices.

Market Dynamics and Pricing Volatility

The price of petroleum coke is influenced by various market dynamics, including crude oil prices and demand from the aluminum sector. Understanding these factors is critical for industry stakeholders to navigate potential volatility in sourcing petcoke.

Frequently Asked Questions (FAQs)

1. What is petroleum coke used for in aluminum production?

Petroleum coke is primarily used to produce carbon anodes, which are essential for the electrolytic reduction process in aluminum production.

2. Why is petroleum coke preferred over other carbon sources?

Petroleum coke is cost-effective, has high carbon content, excellent electrical conductivity, and low sulfur levels, making it a superior choice for aluminum manufacturers.

3. What are the environmental impacts of petroleum coke?

While petroleum coke has advantages, its combustion can produce air pollutants. Sustainable practices and technologies are essential to minimize these impacts.

4. How does the anode production process work?

The anode production involves mixing petroleum coke with pitch, molding the mixture, baking it to harden, and finally using it in the electrolytic reduction of aluminum.

5. What are the future trends for petroleum coke in the aluminum industry?

Emerging trends include recycling initiatives, exploring alternative feedstocks, and integrating carbon capture technologies to enhance sustainability.

Conclusion

Petroleum coke plays an indispensable role in aluminum production, primarily as a key component of carbon anodes. Its unique properties, such as high carbon content, low sulfur levels, and excellent conductivity, make it a preferred choice in the industry. As the aluminum sector continues to evolve, the focus on sustainability and innovative practices will shape the future of petroleum coke usage. Understanding the intricacies of this critical material not only highlights its importance but also sets the stage for ongoing advancements in the aluminum manufacturing process.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property