Understanding the Properties of Graphite Square for Advanced Applications

Understanding the Properties of Graphite Square for Advanced Applications

Graphite squares are emerging as crucial components in various advanced applications, thanks to their unique properties and versatility. As industries evolve, the demand for materials that can perform under extreme conditions increases. In this article, we will explore the properties of graphite squares, their manufacturing processes, and their extensive applications across different sectors, providing a detailed understanding that can help you harness their potential effectively.

Table of Contents

- 1. Introduction to Graphite Squares

- 2. Key Properties of Graphite Squares

- 3. Manufacturing Processes of Graphite Squares

- 4. Applications of Graphite Squares in Advanced Industries

- 5. Advantages of Using Graphite Squares

- 6. Challenges in Graphite Square Utilization

- 7. Future Trends in Graphite Square Technology

- 8. Conclusion

- 9. FAQs About Graphite Squares

1. Introduction to Graphite Squares

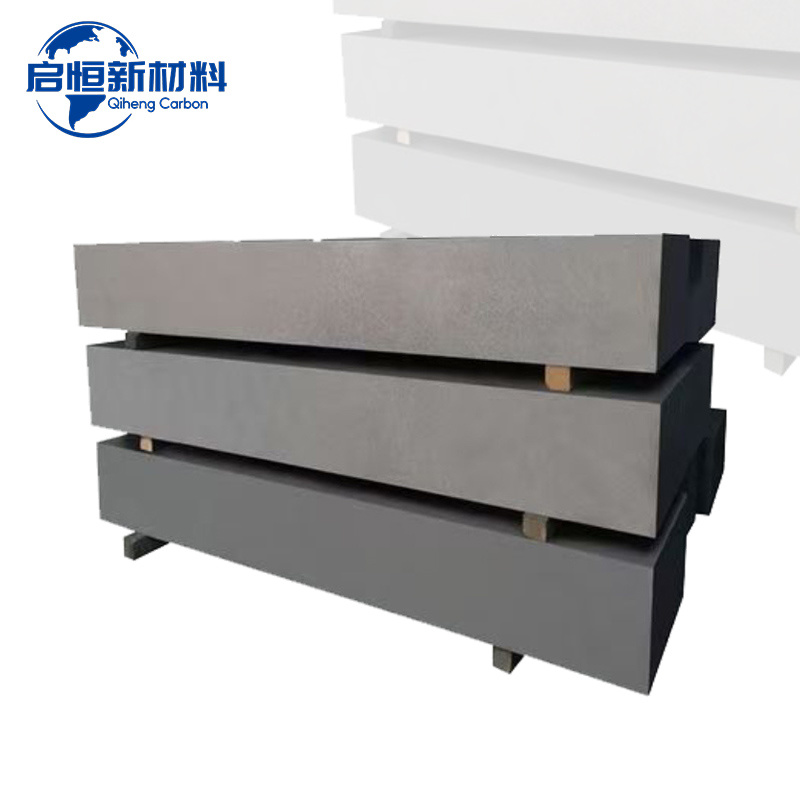

Graphite, a form of carbon, is known for its unique crystalline structure that allows for the formation of graphite squares. These squares are flat, square-shaped pieces of graphite that possess remarkable characteristics, making them suitable for various high-performance applications. Their development has opened new avenues of innovation in multiple sectors, including electronics, energy, and automotive industries.

2. Key Properties of Graphite Squares

Understanding the properties of graphite squares is essential for leveraging their advantages in advanced applications. Below, we will discuss the most significant properties that contribute to their extensive use.

2.1 Thermal Conductivity

Graphite squares exhibit exceptional thermal conductivity, allowing them to efficiently transfer heat. This property is particularly valuable in applications requiring efficient heat dissipation, such as in semiconductor devices and high-performance electronic components. With a thermal conductivity that can exceed 2000 W/m·K, graphite squares are preferable in scenarios where overheating is a concern.

2.2 Electrical Conductivity

Another outstanding property of graphite squares is their electrical conductivity. Graphite is a good conductor of electricity due to the mobility of its delocalized electrons. This characteristic makes graphite squares ideal for use in batteries, electrodes, and other electronic applications where efficient electrical conduction is paramount.

2.3 Chemical Resistance

Graphite squares exhibit excellent chemical resistance, particularly against acids and bases. This resistance ensures their longevity and reliability in harsh chemical environments, making them suitable for applications in chemical processing and storage. Their inert nature also prevents reactions that could compromise the integrity of the systems in which they are used.

3. Manufacturing Processes of Graphite Squares

The manufacturing of graphite squares involves several processes that ensure their structural integrity and performance characteristics. These processes typically include:

- Mining and Sourcing: The first step involves extracting natural graphite from mines. This graphite is usually processed and purified before being used.

- Graphitization: For synthetic graphite squares, carbon-based materials undergo a process called graphitization, where they are heated to high temperatures to form crystalline structures.

- Shaping: The graphite is then shaped into squares using techniques such as extrusion or compression molding, ensuring uniformity and desired dimensions.

- Finishing: Finally, the squares undergo finishing processes to enhance their surface quality and performance, including machining or coating, depending on the application requirements.

4. Applications of Graphite Squares in Advanced Industries

Graphite squares are utilized in a broad range of applications due to their versatile properties. Below, we highlight some key areas where they have made significant impacts.

4.1 Usage in Electronics

In the electronics industry, graphite squares are widely employed in the manufacturing of heat sinks and electronic packaging. Their high thermal conductivity helps in managing heat dispersion, enhancing the performance and longevity of electronic devices, including computers and smartphones. Moreover, they are also used in battery technologies, particularly in lithium-ion batteries, where their electrical conductivity plays a crucial role.

4.2 Applications in Energy

Graphite squares are critical in the energy sector, especially in batteries and fuel cells. Their resilience and conductivity make them ideal for components that require high performance and reliability. Additionally, in renewable energy applications, such as solar panels, graphite squares contribute to efficient energy transfer and storage systems, enhancing overall energy efficiency.

4.3 Role in the Automotive Industry

In the automotive industry, graphite squares are being increasingly used in electric vehicles (EVs). They serve as critical components in batteries, where their properties ensure optimal performance. Furthermore, their lightweight nature contributes to fuel efficiency, making them an attractive choice for modern automotive designs focused on sustainability.

5. Advantages of Using Graphite Squares

The utilization of graphite squares comes with numerous advantages, including:

- High Performance: Due to their superior thermal and electrical conductivity, graphite squares enhance the performance of various applications.

- Durability: Their chemical resistance ensures longevity and reliability, even in challenging environments.

- Lightweight: Graphite is significantly lighter than metals, which is particularly beneficial in applications where weight savings are critical.

- Cost-Effectiveness: As demand increases, the cost of production for graphite squares is becoming more economical, making them a cost-effective solution for various industries.

6. Challenges in Graphite Square Utilization

While graphite squares offer numerous benefits, there are challenges associated with their use:

- Sourcing Quality Material: The quality of graphite can vary significantly, impacting the performance of the final products. Ensuring a reliable supply of high-quality graphite is essential.

- Manufacturing Limitations: Some manufacturing processes may limit the scalability and customization of graphite squares, particularly for specialized applications.

- Environmental Concerns: Mining and processing of graphite can have environmental impacts, necessitating sustainable practices and innovations in production.

7. Future Trends in Graphite Square Technology

The future of graphite square technology looks promising, with several trends emerging:

- Advancements in Nanotechnology: Research is ongoing into the nano-structuring of graphite to enhance its properties for even more specialized applications.

- Recycling Initiatives: Efforts are being made to recycle graphite from used batteries and other products, promoting sustainability and resource efficiency.

- Innovative Applications: New applications in fields like aerospace, military, and biomedical engineering are being explored, expanding the use of graphite squares beyond traditional boundaries.

8. Conclusion

Graphite squares represent a remarkable advancement in material science, combining exceptional properties with versatility for a wide range of applications. Their unique characteristics, including thermal and electrical conductivity, chemical resistance, and lightweight nature, make them indispensable in modern industries. As we continue to explore their potential, graphite squares will undoubtedly play an increasingly vital role in driving innovation and efficiency in advanced applications. Understanding their properties and applications is crucial for industries looking to leverage this material to enhance performance and sustainability.

9. FAQs About Graphite Squares

What are graphite squares used for?

Graphite squares are utilized in various applications, including electronics, energy storage solutions, and automotive components, due to their outstanding thermal and electrical conductivity.

How are graphite squares manufactured?

Graphite squares are manufactured through processes involving mining, graphitization, shaping, and finishing to ensure their structural integrity and performance capabilities.

What are the advantages of using graphite squares in electronics?

The advantages include improved thermal management, enhanced electrical conductivity, and overall performance improvement in devices like batteries and heat sinks.

Are there any environmental concerns associated with graphite production?

Yes, the mining and processing of graphite can have environmental impacts. Sustainable practices are essential to mitigate these issues and promote responsible sourcing.

What future trends are expected for graphite squares?

Future trends include advancements in nanotechnology, recycling initiatives, and expanding applications in various fields, enhancing the versatility and sustainability of graphite squares.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries