Unlocking the Potential of Graphite Powder in Metallurgy and Energy Industries

Summary:

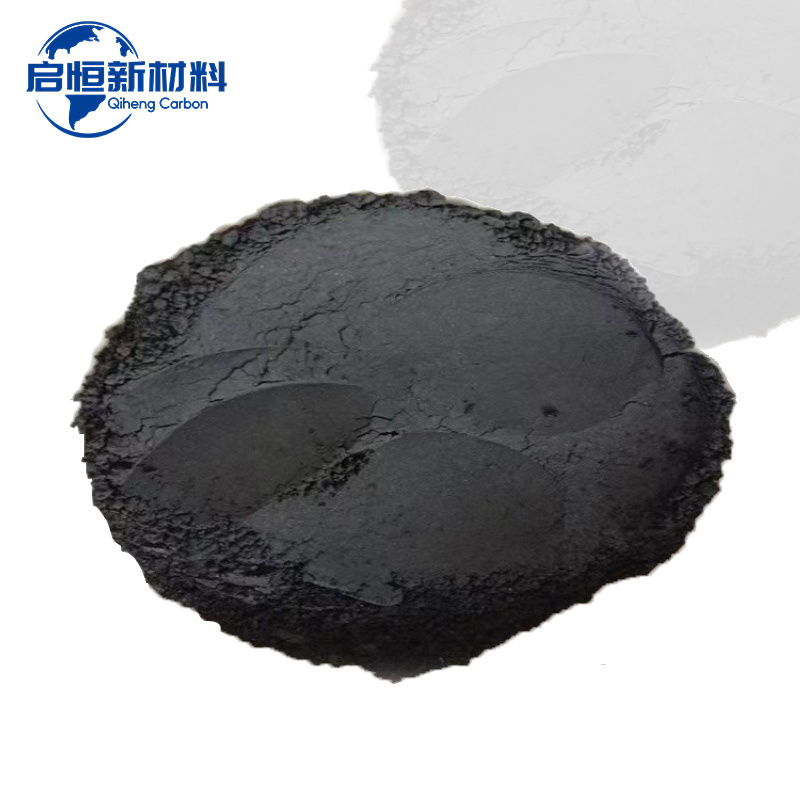

Graphite powder is a versatile material widely utilized in the metallurgy and energy sectors, particularly in the production of non-metallic mineral products. Its unique characteristics, such as thermal conductivity, lubricity, and chemical stability, make it an essential ingredient in various industrial applications.

One of the primary uses of graphite powder is in the manufacture of lubricants.

Graphite powder is a versatile material widely utilized in the metallurgy and energy sectors, particularly in the production of non-metallic mineral products. Its unique characteristics, such as thermal conductivity, lubricity, and chemical stability, make it an essential ingredient in various industrial applications.

One of the primary uses of graphite powder is in the manufacture of lubricants. Its exceptional lubricating properties help reduce friction between moving parts, which is critical in machinery and automotive applications. This not only enhances the lifespan of equipment but also improves energy efficiency, making operations more cost-effective.

In metallurgy, graphite powder plays a vital role as a reducing agent in the production of metals from their ores. It facilitates the extraction of metals by lowering the melting point of the ore, thereby reducing energy consumption during the smelting process. Additionally, graphite powder is employed in the production of electrodes for electric arc furnaces, which are essential in steelmaking and other metallurgical processes. These electrodes benefit from the high thermal and electrical conductivity of graphite, ensuring efficient operation.

Moreover, graphite powder is increasingly being recognized for its applications in the energy sector, particularly in battery technology. As industries shift towards sustainable energy solutions, graphite powder is gaining prominence in the production of lithium-ion batteries. Its high conductivity and ability to intercalate lithium ions make it an ideal anode material, contributing to more efficient energy storage and longer battery life.

Another noteworthy application of graphite powder is in the production of refractory materials. These materials are essential in high-temperature industrial processes, providing thermal resistance and durability. Graphite powder enhances the mechanical properties of refractories, making them suitable for use in furnaces and kilns.

Furthermore, the versatility of graphite powder extends to its use in composites and coatings. Its ability to improve mechanical strength and thermal stability makes it a valuable additive in various composite materials, enhancing performance in automotive, aerospace, and construction applications.

In conclusion, graphite powder is a critical component in the metallurgy and energy industries, with numerous applications ranging from lubricants and reducing agents to battery materials and refractories. As technology evolves, the demand for high-quality graphite powder is expected to grow, driven by its indispensable role in enhancing industrial processes and promoting energy efficiency. Understanding its properties and applications can help industries leverage this valuable resource to achieve greater productivity and sustainability.

One of the primary uses of graphite powder is in the manufacture of lubricants. Its exceptional lubricating properties help reduce friction between moving parts, which is critical in machinery and automotive applications. This not only enhances the lifespan of equipment but also improves energy efficiency, making operations more cost-effective.

In metallurgy, graphite powder plays a vital role as a reducing agent in the production of metals from their ores. It facilitates the extraction of metals by lowering the melting point of the ore, thereby reducing energy consumption during the smelting process. Additionally, graphite powder is employed in the production of electrodes for electric arc furnaces, which are essential in steelmaking and other metallurgical processes. These electrodes benefit from the high thermal and electrical conductivity of graphite, ensuring efficient operation.

Moreover, graphite powder is increasingly being recognized for its applications in the energy sector, particularly in battery technology. As industries shift towards sustainable energy solutions, graphite powder is gaining prominence in the production of lithium-ion batteries. Its high conductivity and ability to intercalate lithium ions make it an ideal anode material, contributing to more efficient energy storage and longer battery life.

Another noteworthy application of graphite powder is in the production of refractory materials. These materials are essential in high-temperature industrial processes, providing thermal resistance and durability. Graphite powder enhances the mechanical properties of refractories, making them suitable for use in furnaces and kilns.

Furthermore, the versatility of graphite powder extends to its use in composites and coatings. Its ability to improve mechanical strength and thermal stability makes it a valuable additive in various composite materials, enhancing performance in automotive, aerospace, and construction applications.

In conclusion, graphite powder is a critical component in the metallurgy and energy industries, with numerous applications ranging from lubricants and reducing agents to battery materials and refractories. As technology evolves, the demand for high-quality graphite powder is expected to grow, driven by its indispensable role in enhancing industrial processes and promoting energy efficiency. Understanding its properties and applications can help industries leverage this valuable resource to achieve greater productivity and sustainability.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property