How to Select the Best Graphite Electrode Connector for Your Project: A Comprehensive Guide

Summary:

How to Select the Best Graphite Electrode Connector for Your Project

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. Understanding Graphite Electrode Applications

3. Key Features to Consider When Selecting a Connector

3.1 Material Composition

3.2 Size and Compatibility

3.3 Thermal Conductivity

3.4 Electrical Resistance

4. Types of Graphite Electrode Connectors

4.1 Pin Connect

How to Select the Best Graphite Electrode Connector for Your Project

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. Understanding Graphite Electrode Applications

3. Key Features to Consider When Selecting a Connector

3.1 Material Composition

3.2 Size and Compatibility

3.3 Thermal Conductivity

3.4 Electrical Resistance

4. Types of Graphite Electrode Connectors

4.1 Pin Connectors

4.2 Socket Connectors

4.3 Quick Disconnect Connectors

5. Assessing Manufacturer Reputation and Quality Assurance

6. Cost vs. Quality: Finding the Right Balance

7. Installation and Maintenance of Graphite Electrode Connectors

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Graphite Electrode Connectors

Graphite electrode connectors play a crucial role in various industrial applications, especially in electric arc furnaces and other high-temperature environments. These connectors are designed to establish a reliable electrical connection between graphite electrodes, ensuring efficient energy transfer. Choosing the right graphite electrode connector can significantly impact the performance and longevity of your equipment.

2. Understanding Graphite Electrode Applications

Before diving into the selection process, it's essential to understand the applications where graphite electrode connectors are utilized. Commonly used in steelmaking, foundry operations, and aluminum production, these connectors facilitate the transfer of electrical current to create high temperatures necessary for melting metals. The specific requirements for connectors can vary based on the application, highlighting the importance of selecting the right type for your project.

3. Key Features to Consider When Selecting a Connector

Selecting the best graphite electrode connector requires a thorough evaluation of several key features. Below, we outline the critical factors to consider:

3.1 Material Composition

The material from which the connector is made is vital for its performance. High-quality materials can withstand extreme temperatures and corrosive environments. Typically, copper alloys are preferred due to their excellent conductivity and durability. Ensure that the connector material is compatible with the graphite electrodes used in your project.

3.2 Size and Compatibility

Correct sizing is essential for a secure and efficient connection. Verify the dimensions of both the electrodes and the connectors. Mismatches can lead to poor connections and potential equipment failure. Additionally, consider how the connector fits within the overall system to ensure compatibility with your existing setup.

3.3 Thermal Conductivity

**Thermal conductivity** is crucial for the efficient transfer of electricity and heat. Select connectors that offer high thermal conductivity to minimize heat loss and ensure that the electrodes operate at optimal temperatures. Connectors with high thermal conductivity also reduce the risk of overheating and extend the lifespan of both the connector and the electrodes.

3.4 Electrical Resistance

Low electrical resistance is vital for effective energy transfer. When selecting a connector, look for options that have minimal resistance to enhance the overall efficiency of your project. High-resistance connectors can lead to energy loss, increased heating, and potential equipment damage.

4. Types of Graphite Electrode Connectors

There are several types of graphite electrode connectors available, each designed for specific applications. Understanding these variations can help you choose the right connector for your needs.

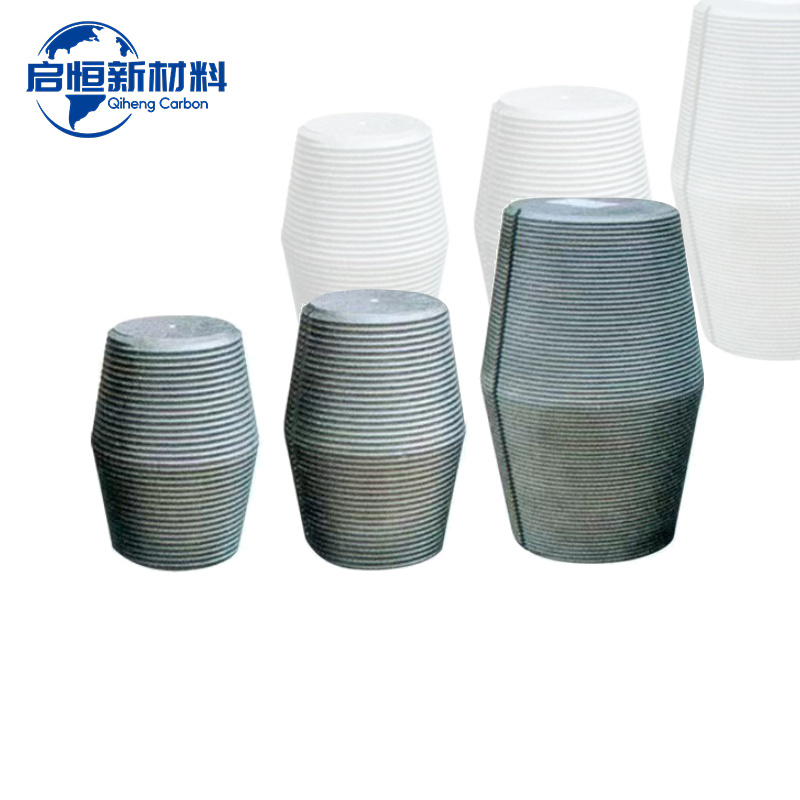

4.1 Pin Connectors

Pin connectors consist of a male and female component that securely fits together. They are often used in applications requiring a robust connection. Pin connectors are known for their ease of use and reliability, making them a popular choice in various industries.

4.2 Socket Connectors

Socket connectors provide a secure and stable connection, often used in environments where frequent disconnections are necessary. Their design allows for easy installation and removal, which is beneficial in applications requiring regular maintenance.

4.3 Quick Disconnect Connectors

Quick disconnect connectors are designed for rapid connections and disconnections, making them ideal for mobile or temporary setups. They offer convenience without compromising performance. If your project requires frequent adjustments or changes, these connectors may be the best choice.

5. Assessing Manufacturer Reputation and Quality Assurance

When selecting a graphite electrode connector, it's essential to consider the reputation of the manufacturer. Research manufacturers known for their quality assurance practices and industry certifications. Selecting connectors from reputable suppliers ensures you receive a product that meets safety and performance standards.

6. Cost vs. Quality: Finding the Right Balance

While cost is a significant factor in your decision-making process, it shouldn't overshadow quality. Investing in high-quality connectors may require a higher initial expenditure, but it can lead to reduced maintenance costs, improved performance, and longer lifespan. Weighing the long-term benefits against short-term costs is crucial for making the right choice.

7. Installation and Maintenance of Graphite Electrode Connectors

Proper installation and maintenance of graphite electrode connectors are vital for optimal performance. Ensure that connectors are installed according to the manufacturer's instructions to prevent issues. Regular maintenance checks can help identify wear and tear early, allowing for timely replacements and minimizing downtime.

8. Frequently Asked Questions (FAQs)

1. What is a graphite electrode connector?

A graphite electrode connector is a component used to connect graphite electrodes in high-temperature industrial applications, facilitating efficient electrical energy transfer.

2. How do I know which connector is suitable for my project?

Consider factors such as material composition, size compatibility, thermal conductivity, and electrical resistance when selecting a connector for your project.

3. Are there different types of graphite electrode connectors?

Yes, common types include pin connectors, socket connectors, and quick disconnect connectors, each designed for various applications and connection needs.

4. Why is material composition important for connectors?

Material composition affects the connector's durability, thermal conductivity, and electrical resistance, impacting overall system performance.

5. How can maintenance affect the lifespan of graphite electrode connectors?

Regular maintenance helps identify potential issues early, preventing damage and prolonging the lifespan of the connectors and associated equipment.

9. Conclusion

Selecting the best graphite electrode connector for your project is a critical decision that can significantly affect the efficiency and longevity of your operations. By considering essential factors such as material composition, compatibility, thermal conductivity, and manufacturer reputation, you can make an informed choice that meets your project's specific needs. Prioritizing quality over cost and ensuring proper installation and maintenance will contribute to the successful implementation of your graphite electrode systems.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property