The Crucial Role of Quality Control in Graphite Electrode Production: Ensuring Excellence and Reliability

Summary:

The Importance of Quality Control in Graphite Electrode Production

Table of Contents

Introduction: Understanding Graphite Electrodes

What Are Graphite Electrodes?

The Role of Graphite Electrodes in Various Industries

Quality Control in Graphite Electrode Production

Key Quality Control Processes

Challenges in Quality Control for Graphite Electrodes

Best Practices for En

The Importance of Quality Control in Graphite Electrode Production

Table of Contents

- Introduction: Understanding Graphite Electrodes

- What Are Graphite Electrodes?

- The Role of Graphite Electrodes in Various Industries

- Quality Control in Graphite Electrode Production

- Key Quality Control Processes

- Challenges in Quality Control for Graphite Electrodes

- Best Practices for Ensuring Quality in Production

- The Future of Quality Control in Graphite Production

- Conclusion

- FAQs

Introduction: Understanding Graphite Electrodes

Graphite electrodes play a pivotal role in modern metallurgy and energy production, particularly in electric arc furnaces (EAFs) and various types of metallurgical processes. As the demand for steel and other metals continues to grow, the production of high-quality graphite electrodes becomes increasingly critical. Quality control is essential in this production process to ensure that the electrodes meet the required specifications and perform effectively in harsh industrial environments.

What Are Graphite Electrodes?

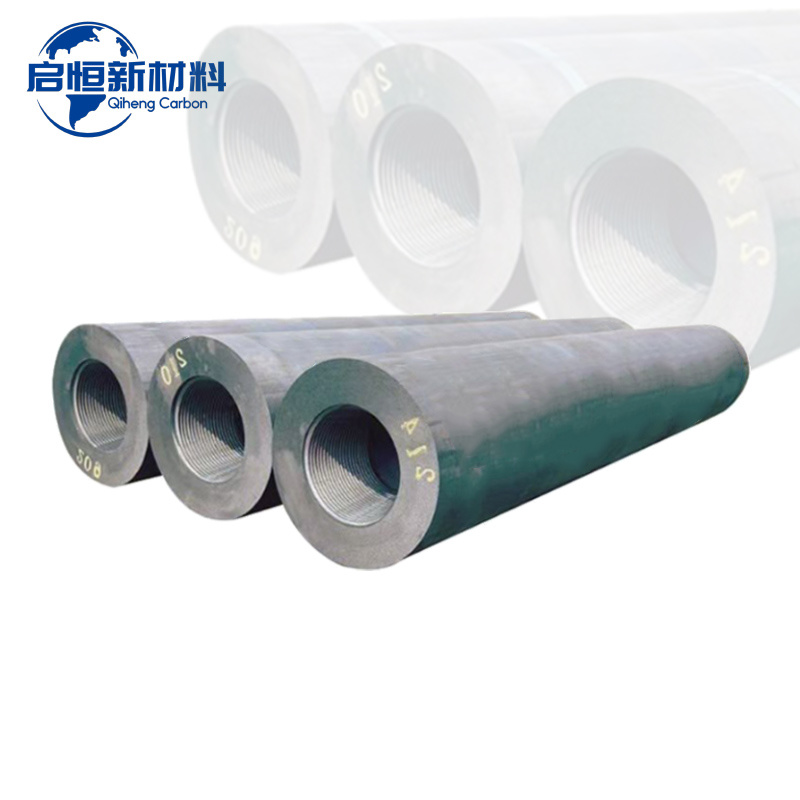

Graphite electrodes are cylindrical rods made from high-purity graphite and are used to conduct electricity in electric arc furnaces. These electrodes facilitate the melting of scrap metal and other materials, making them essential in steel production and other metallurgical processes. The properties that make graphite electrodes desirable include high electrical conductivity, thermal stability, and resistance to thermal shock.

The Role of Graphite Electrodes in Various Industries

In addition to their primary use in steel manufacturing, graphite electrodes are also utilized in the production of aluminum, copper, and silicon. As industries strive for efficiency and sustainability, the demand for high-performance graphite electrodes has surged. Consequently, ensuring the quality of these electrodes is vital for the performance and sustainability of industrial processes.

Quality Control in Graphite Electrode Production

Quality control encompasses a series of processes and measures that ensure products meet specified standards and specifications. In graphite electrode production, quality control begins with the selection of raw materials, such as petroleum coke and pitch, and extends through all stages of production, including mixing, molding, baking, and machining. Each step requires careful monitoring to detect and correct any deviations from quality standards.

Importance of Raw Material Quality

The quality of raw materials directly impacts the performance of the final product. Hence, conducting thorough inspections and tests on materials before production is critical. Materials should be analyzed for impurities, particle size distribution, and chemical composition to identify any potential issues that could affect the quality of the electrodes.

Key Quality Control Processes

Several key processes are integral to maintaining quality control in graphite electrode production. These processes include:

1. Material Testing

Before production begins, raw materials undergo rigorous testing. This includes checking the electrical conductivity, density, and thermal properties of the materials to ensure they meet industry standards.

2. In-Process Monitoring

During the manufacturing process, continuous monitoring is essential. Parameters such as temperature, pressure, and mixing times are closely regulated to prevent defects. Automated systems can assist in monitoring these variables in real-time.

3. Final Inspection and Testing

After production, electrodes must pass through final inspections. This includes dimensional checks, visual inspections for surface defects, and performance testing to ensure they meet quality specifications before shipping.

Challenges in Quality Control for Graphite Electrodes

Despite the best efforts in quality control, several challenges persist in the production of graphite electrodes:

1. Variability in Raw Materials

The quality of raw materials can vary significantly, leading to inconsistencies in the final product. Suppliers must be carefully selected, and materials should be tested frequently to maintain quality.

2. Process Complexity

The production of graphite electrodes involves multiple stages, each with its own set of variables. Managing these complexities can be challenging, requiring sophisticated monitoring systems and skilled personnel.

3. Evolving Industry Standards

As technology advances, industry standards for quality control are continually evolving. Manufacturers must stay updated on these changes and adapt their quality control processes accordingly.

Best Practices for Ensuring Quality in Production

Implementing best practices in quality control can significantly enhance the reliability and performance of graphite electrodes:

1. Develop a Quality Management System (QMS)

Establishing a robust QMS can streamline monitoring and inspection processes, ensuring consistent quality throughout production. This system should include documentation, procedures, and employee training.

2. Invest in Technology

Utilizing advanced technologies, such as automated inspection systems and data analytics, can help identify defects earlier in the production process, reducing waste and enhancing overall quality.

3. Foster a Quality-Centric Culture

Encouraging a culture of quality among employees can lead to greater awareness of quality control measures. Regular training and workshops can enhance employees' understanding of quality standards and their importance.

The Future of Quality Control in Graphite Production

As the graphite electrode industry continues to expand, the importance of quality control will only increase. Innovations in materials science and manufacturing technology will drive improvements in quality standards. Additionally, the integration of artificial intelligence (AI) and machine learning (ML) into quality control processes can lead to more precise monitoring and predictive capabilities, further enhancing product reliability.

Conclusion

Quality control is a cornerstone of graphite electrode production. By focusing on maintaining high standards throughout the production process, manufacturers can ensure that their products meet the demands of various industrial applications. As the industry evolves, the adoption of advanced technologies and best practices will be essential in overcoming challenges and delivering high-quality graphite electrodes that contribute to the efficiency and sustainability of metallurgy and energy sectors.

FAQs

1. Why is quality control critical in graphite electrode production?

Quality control is essential in ensuring that graphite electrodes meet the necessary performance standards required for their various industrial applications. It helps prevent defects that could lead to operational failures.

2. What are the common materials used in graphite electrode production?

The primary materials include petroleum coke and pitch, which are selected for their high carbon content and purity.

3. How can manufacturers ensure the quality of raw materials?

Manufacturers should conduct thorough testing on raw materials, including analyzing chemical composition and checking for impurities, before using them in production.

4. What role does technology play in quality control?

Technology enhances quality control by automating monitoring processes, providing real-time data, and identifying defects earlier in production.

5. What are the future trends in quality control for graphite electrodes?

Future trends include the integration of AI and ML into quality control processes, which can improve monitoring precision and predictive capabilities, leading to enhanced product quality.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property