Unlocking the Potential of Graphite Blocks in Metallurgy and Energy Sectors

Summary:

Graphite blocks are essential materials in the metallurgy and energy sectors, particularly in the production of non-metal mineral products. Their unique properties, such as high thermal conductivity, low coefficient of thermal expansion, and excellent lubricity, make them invaluable in various applications. Understanding the significance of graphite blocks can help professionals in these industrie

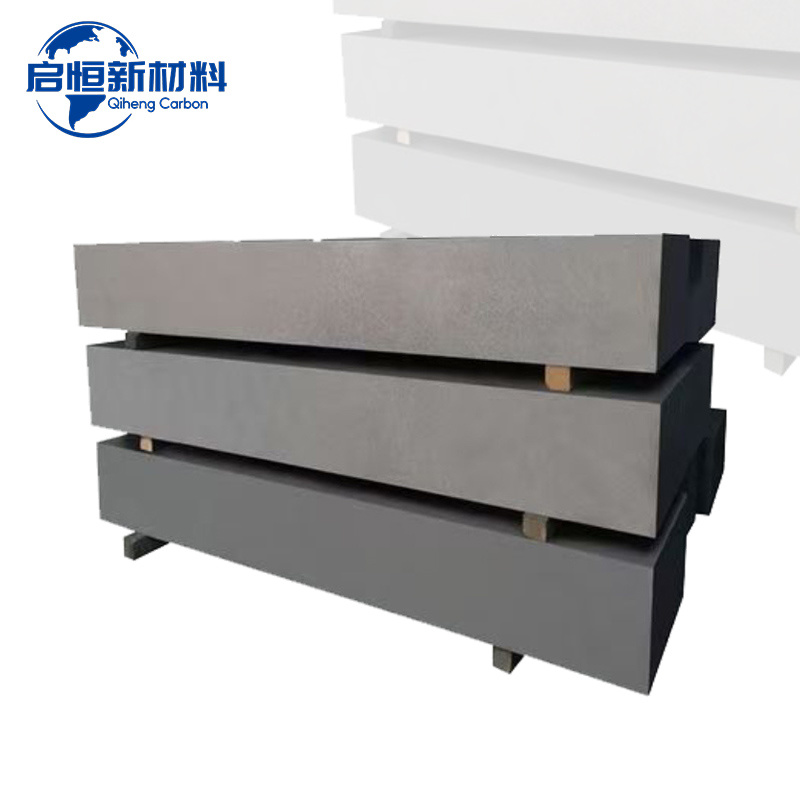

Graphite blocks are essential materials in the metallurgy and energy sectors, particularly in the production of non-metal mineral products. Their unique properties, such as high thermal conductivity, low coefficient of thermal expansion, and excellent lubricity, make them invaluable in various applications. Understanding the significance of graphite blocks can help professionals in these industries optimize their operations and improve product performance.

In metallurgy, graphite blocks are widely used in the manufacturing of electrodes for electric arc furnaces (EAFs). These electrodes are critical for melting scrap metal and producing high-quality steel. The use of graphite blocks in this context ensures consistent heat generation and efficient energy transfer, leading to reduced operational costs and improved production rates. Additionally, graphite blocks can withstand the extreme temperatures and chemical reactions that occur during the metal melting process, enhancing their durability and lifespan.

Moreover, graphite blocks have applications in the energy sector, particularly in the production of batteries. As the demand for renewable energy sources continues to grow, the role of graphite in lithium-ion batteries has become increasingly important. Graphite blocks serve as the anode material in these batteries, offering excellent conductivity and stability. This is vital for ensuring the performance and longevity of batteries used in electric vehicles, energy storage systems, and portable electronics.

Another significant aspect of graphite blocks is their contribution to sustainability. As industries strive to reduce their carbon footprint, the use of high-quality graphite blocks can lead to more efficient manufacturing processes. By optimizing energy consumption and minimizing waste, companies can align with global sustainability goals while maintaining competitive advantage.

The versatility of graphite blocks extends to their use in various other applications, such as heat exchangers, furnaces, and molds. Their ability to withstand high temperatures and corrosive environments makes them ideal for a range of thermal management solutions. Furthermore, ongoing advancements in material science are paving the way for the development of enhanced graphite products that offer even greater performance benefits.

In conclusion, graphite blocks play a pivotal role in the metallurgy and energy sectors, providing essential benefits that drive efficiency and sustainability. Professionals in these industries should consider the potential of high-quality graphite blocks to enhance their operations and product offerings. By integrating these materials into their processes, companies can achieve superior results, ultimately leading to growth and innovation in an increasingly competitive marketplace.

In metallurgy, graphite blocks are widely used in the manufacturing of electrodes for electric arc furnaces (EAFs). These electrodes are critical for melting scrap metal and producing high-quality steel. The use of graphite blocks in this context ensures consistent heat generation and efficient energy transfer, leading to reduced operational costs and improved production rates. Additionally, graphite blocks can withstand the extreme temperatures and chemical reactions that occur during the metal melting process, enhancing their durability and lifespan.

Moreover, graphite blocks have applications in the energy sector, particularly in the production of batteries. As the demand for renewable energy sources continues to grow, the role of graphite in lithium-ion batteries has become increasingly important. Graphite blocks serve as the anode material in these batteries, offering excellent conductivity and stability. This is vital for ensuring the performance and longevity of batteries used in electric vehicles, energy storage systems, and portable electronics.

Another significant aspect of graphite blocks is their contribution to sustainability. As industries strive to reduce their carbon footprint, the use of high-quality graphite blocks can lead to more efficient manufacturing processes. By optimizing energy consumption and minimizing waste, companies can align with global sustainability goals while maintaining competitive advantage.

The versatility of graphite blocks extends to their use in various other applications, such as heat exchangers, furnaces, and molds. Their ability to withstand high temperatures and corrosive environments makes them ideal for a range of thermal management solutions. Furthermore, ongoing advancements in material science are paving the way for the development of enhanced graphite products that offer even greater performance benefits.

In conclusion, graphite blocks play a pivotal role in the metallurgy and energy sectors, providing essential benefits that drive efficiency and sustainability. Professionals in these industries should consider the potential of high-quality graphite blocks to enhance their operations and product offerings. By integrating these materials into their processes, companies can achieve superior results, ultimately leading to growth and innovation in an increasingly competitive marketplace.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property