How Graphite Square Can Optimize Your Production Line for Maximum Efficiency

How Graphite Square Can Optimize Your Production Line for Maximum Efficiency

Table of Contents

- Introduction to Graphite Square in Production Lines

- Understanding Graphite and Carbon Products

- The Benefits of Using Graphite Square

- Strategies to Optimize Your Production Line with Graphite Square

- Applications of Graphite Square Across Industries

- Case Studies: Successful Implementations of Graphite Square

- Common Challenges and Solutions in Using Graphite

- The Future of Graphite in Production Processes

- FAQs about Graphite Square Optimization

- Conclusion

Introduction to Graphite Square in Production Lines

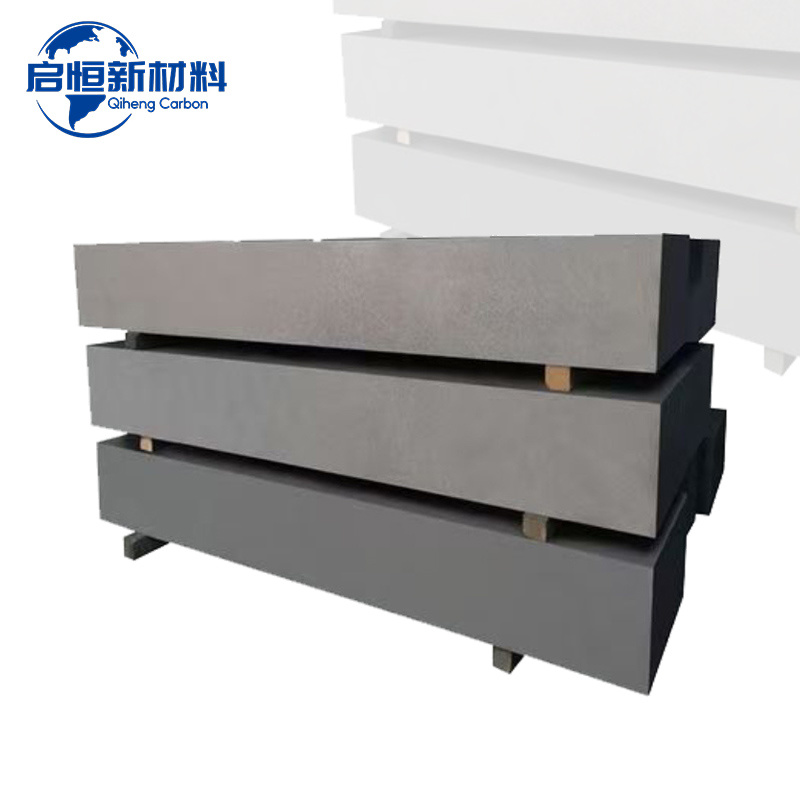

In an era where efficiency and productivity define the success of manufacturing operations, the pursuit of innovative materials is paramount. **Graphite Square** emerges as a key player in this landscape, revolutionizing production lines across various sectors. With its unique properties, including exceptional thermal conductivity, chemical resistance, and tribological performance, Graphite Square has the potential to optimize manufacturing processes significantly.

This article delves into the myriad ways Graphite Square can enhance production, discussing its benefits, applications, and practical strategies for implementation.

Understanding Graphite and Carbon Products

Graphite is a naturally occurring form of carbon, known for its layered structure, which allows for remarkable flexibility and electrical conductivity. **Graphite products**, particularly Graphite Square, are engineered to leverage these properties for various industrial applications.

###

Composition and Characteristics of Graphite

Graphite's composition primarily consists of carbon atoms arranged in a hexagonal lattice. This configuration results in several key characteristics:

- **High thermal conductivity**: Ideal for applications requiring efficient heat dissipation.

- **Low friction coefficients**: Makes graphite suitable for lubrication purposes.

- **Chemical inertness**: Resists degradation in harsh environments.

###

Types of Graphite Products

Various graphite products are available, including:

- Natural graphite

- Synthetic graphite

- Expanded graphite

- Graphite composites

Each type offers unique properties, making them suitable for specific applications in different industries.

The Benefits of Using Graphite Square

Integrating Graphite Square into your production line can yield numerous benefits, enhancing operational efficiency and product quality.

###

1. Enhanced Efficiency

Graphite Square's thermal and electrical conductivity facilitates faster processing times, leading to increased output rates. This efficiency translates into more products produced in less time, optimizing your production line.

###

2. Cost Reduction

By utilizing Graphite Square, manufacturers can reduce wear and tear on equipment, minimizing maintenance costs and prolonging the life of machinery. Additionally, its ability to operate effectively in high-temperature environments can lower energy consumption.

###

3. Improved Product Quality

Graphite Square ensures consistent performance, which contributes to higher-quality end products. Its chemical inertness prevents contamination, ensuring the integrity of materials used in production.

###

4. Versatility in Applications

Graphite Square is adaptable to various industries, from automotive to electronics. This versatility allows manufacturers to implement it in multiple processes, enhancing overall production line effectiveness.

Strategies to Optimize Your Production Line with Graphite Square

To maximize the benefits of Graphite Square, consider the following strategies tailored to your production needs.

###

1. Assess Your Current Production Processes

Evaluate your existing production lines to identify areas where Graphite Square can be integrated. Focus on processes that require thermal management or lubrication, as these are prime candidates for optimization.

###

2. Implement Graphite Square in Key Applications

Explore specific applications such as:

- Heat exchangers

- Bearings and seals

- Electrical contacts and connectors

Incorporating Graphite Square in these areas can lead to significant performance gains.

###

3. Train Your Workforce

Ensure that your team understands the properties and handling of Graphite Square. Proper training can prevent misuse and maximize the material's advantages.

###

4. Monitor Performance and Make Adjustments

Regularly monitor production metrics to evaluate the impact of Graphite Square on efficiency and quality. Be prepared to make adjustments as needed, optimizing processes continually.

Applications of Graphite Square Across Industries

Graphite Square finds application in various sectors, showcasing its versatility and efficiency.

###

1. Automotive Industry

In the automotive sector, Graphite Square is utilized in brake linings, gaskets, and electrical components, contributing to enhanced performance and longevity.

###

2. Electronics Industry

Graphite Square's electrical conductivity makes it ideal for components such as capacitors and batteries, where reliable performance is essential.

###

3. Aerospace Industry

In aerospace applications, Graphite Square is used in thermal protection systems and components that require lightweight materials with high strength.

###

4. Renewable Energy Sector

With the rise of renewable energy technologies, Graphite Square plays a crucial role in solar panels and wind turbines, helping to optimize energy conversion processes.

Case Studies: Successful Implementations of Graphite Square

Real-world examples highlight the effectiveness of Graphite Square in optimizing production lines.

###

1. Automotive Manufacturer

An automotive manufacturer implemented Graphite Square in its assembly line, leading to a 20% increase in production efficiency. The incorporation of graphite bearings reduced friction and wear, resulting in lower maintenance costs.

###

2. Electronics Firm

An electronics company integrated Graphite Square into its battery production process. The enhanced thermal management properties improved battery life by 15%, benefiting both the manufacturer and end consumers.

Common Challenges and Solutions in Using Graphite

Despite its advantages, integrating Graphite Square can present challenges.

###

1. Handling and Storage

Graphite's properties require careful handling to avoid contamination. Proper storage solutions and training can mitigate this risk.

###

2. Cost Considerations

While Graphite Square can reduce long-term costs, the initial investment may be high. Conducting a comprehensive cost-benefit analysis can help justify the expenditure.

The Future of Graphite in Production Processes

The future of graphite in production lines looks promising, with ongoing research into its applications and enhancements. Advancements in graphite processing and new hybrid materials may further expand its utility, solidifying its position as a cornerstone material for manufacturing.

FAQs about Graphite Square Optimization

###

1. What is Graphite Square?

Graphite Square is a form of graphite product known for its unique properties, which enhance efficiency in various production applications.

###

2. How does Graphite Square improve production efficiency?

By providing excellent thermal conductivity and low friction, Graphite Square can reduce processing times and extend the lifespan of machinery.

###

3. In which industries can Graphite Square be utilized?

Graphite Square is versatile and finds applications in automotive, electronics, aerospace, and renewable energy sectors.

###

4. What are the challenges of using Graphite Square?

Challenges include the need for careful handling and potential initial cost investments, which can be mitigated through proper training and cost-benefit analysis.

###

5. How can I implement Graphite Square in my production line?

Assess your current processes, identify key areas for integration, train your workforce, and continuously monitor and optimize performance.

Conclusion

Integrating **Graphite Square** into your production line is a strategic move that can yield significant improvements in efficiency, cost reduction, and product quality. As industries evolve and demand for high-performance materials increases, Graphite Square stands out as a pivotal solution. By understanding its properties, applications, and optimization strategies, manufacturers can enhance their processes and remain competitive in the market. Embrace the future of production with Graphite Square and unlock unparalleled potential in your operations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries