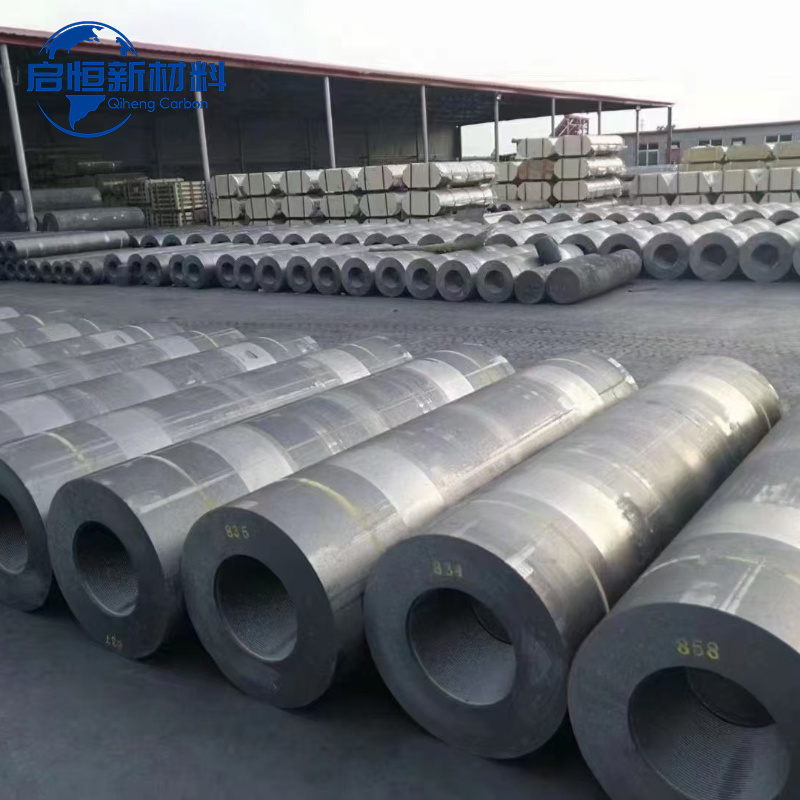

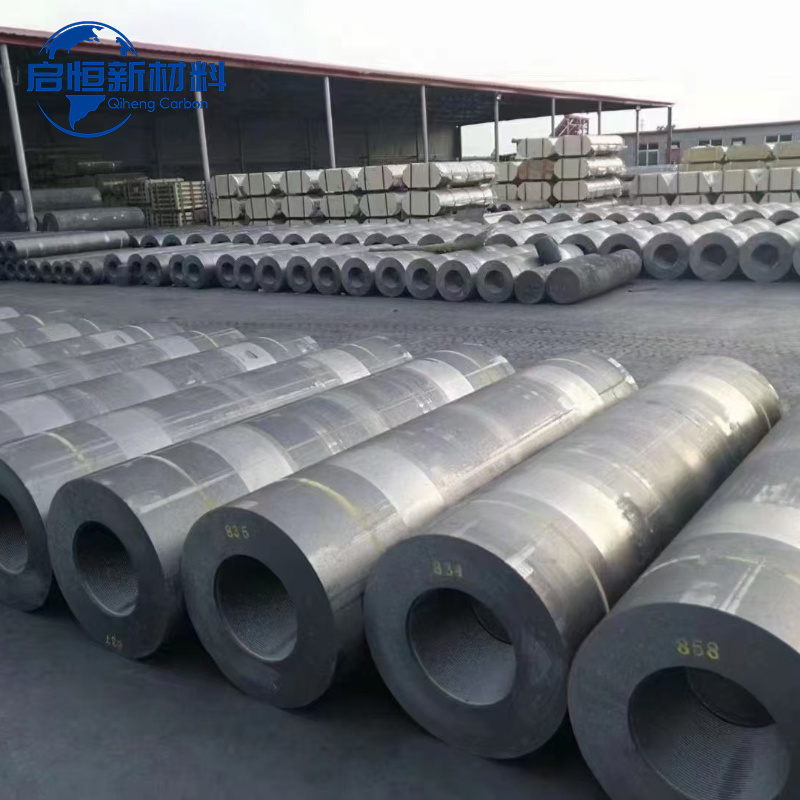

Precision Performance: Customized RP Graphite Electrode from China Exporter Powers Global Industries

The metallurgical and manufacturing sectors continue to demand high-performance solutions, with customized RP graphite electrode from China exporter establishing itself as a reliable choice for electric arc furnace operations worldwide. These precision-engineered components meet rigorous industry standards while offering tailored specifications for diverse smelting applications.

Customized RP graphite electrode from China exporter demonstrates superior electrical and mechanical properties critical for steel production. With resistivity as low as 6.0 μΩ•m for joints and flexural strength reaching 14.0 MPa, these electrodes maintain stability in extreme furnace conditions. Manufacturers report consistent performance across diameters ranging from 200mm to 600mm, with bulk density exceeding 1.70 g/cm³ for optimal current conduction.

Material excellence defines customized RP graphite electrode from China exporter. The controlled ash content (≤0.4%) and low thermal expansion coefficient (≤2.8×10-6/℃) ensure minimal contamination and dimensional stability during high-temperature operations. These characteristics prove particularly valuable for premium steel grades requiring precise thermal management.

Quality consistency characterizes customized RP graphite electrode from China exporter. The electrodes exceed both YB/T4088-2000 standards and stricter internal control benchmarks, with elastic modulus carefully regulated to balance strength and machinability. This attention to detail supports their use in continuous casting processes where electrode performance directly impacts production quality.

For electric arc furnace operations requiring reliable current transmission, customized RP graphite electrode from China exporter delivers consistent performance with engineered precision. As global steel production evolves, these high-quality components continue supporting efficient metal smelting processes across international markets.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries