Understanding Graphite Electrodes for Steel Making: A Key Component in Metallurgical Processes

Summary:

Graphite electrodes are essential components in the production of steel using Electric Arc Furnaces (EAFs). These electrodes serve as conductive materials that facilitate the passage of electric current, generating the temperatures necessary for melting scrap steel and other ferrous materials. The production of steel through this method has gained immense popularity due to its energy efficiency an

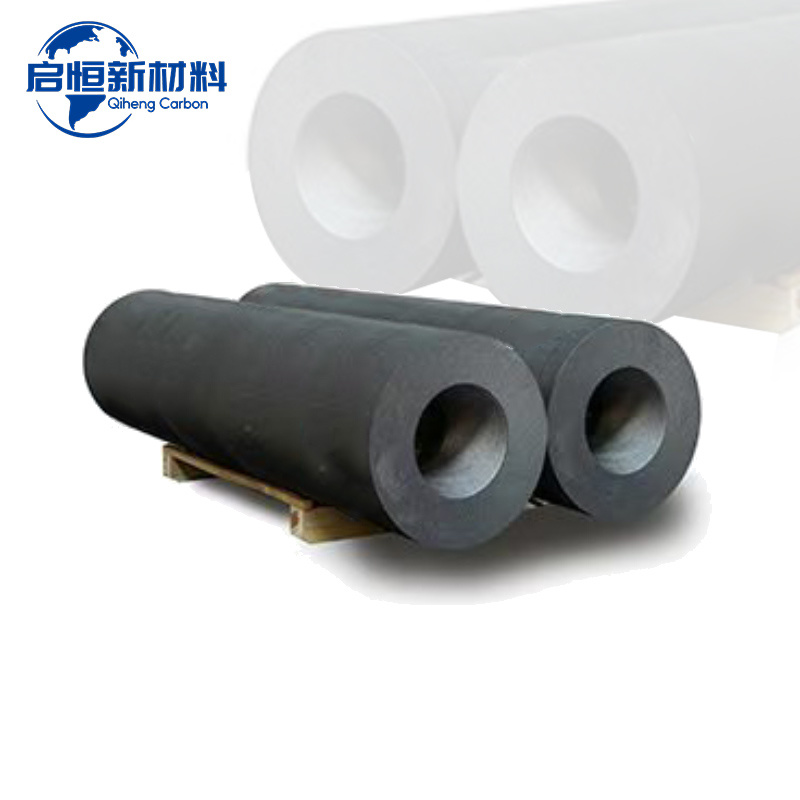

Graphite electrodes are essential components in the production of steel using Electric Arc Furnaces (EAFs). These electrodes serve as conductive materials that facilitate the passage of electric current, generating the temperatures necessary for melting scrap steel and other ferrous materials. The production of steel through this method has gained immense popularity due to its energy efficiency and reduced environmental impact compared to traditional blast furnace methods.

One of the primary advantages of using graphite electrodes in steel-making is their high thermal and electrical conductivity. Graphite, a non-metallic mineral, can withstand extremely high temperatures without degrading, making it an ideal choice for the intense conditions present in steel production. The high carbon content in graphite electrodes not only contributes to their conductivity but also aids in the reduction of iron oxides, enhancing the overall efficiency of the steel-making process.

The quality of graphite electrodes is paramount, as they must endure repeated heating and cooling cycles. Factors such as the purity of the raw materials used in their production, the manufacturing process, and the specific properties of the graphite, including density and electrical resistivity, all influence the performance of these electrodes. High-quality graphite electrodes ensure consistent melting processes, reduce energy consumption, and improve the overall yield of the final steel products.

Furthermore, advancements in technology have led to the development of ultra-high power (UHP) graphite electrodes, which can handle even greater electrical currents and withstand higher temperatures. This innovation has made it possible to increase the production capacity of EAFs, allowing manufacturers to meet the growing demand for steel in various industries, including construction, automotive, and energy.

In addition to their practical applications, the use of graphite electrodes also raises considerations regarding sustainability. The steel industry is under continuous pressure to reduce its carbon footprint, and transitioning to more efficient methods, such as EAFs, aligns with these environmental goals. Graphite electrodes can be produced from recycled materials, further minimizing their environmental impact.

In conclusion, graphite electrodes are a fundamental element in modern steel-making processes, significantly affecting efficiency, quality, and sustainability. Understanding the role and properties of these electrodes helps industry professionals make informed decisions about sourcing and utilizing them in steel production. As the demand for innovative and sustainable metallurgical practices grows, the importance of high-quality graphite electrodes will undoubtedly continue to rise.

One of the primary advantages of using graphite electrodes in steel-making is their high thermal and electrical conductivity. Graphite, a non-metallic mineral, can withstand extremely high temperatures without degrading, making it an ideal choice for the intense conditions present in steel production. The high carbon content in graphite electrodes not only contributes to their conductivity but also aids in the reduction of iron oxides, enhancing the overall efficiency of the steel-making process.

The quality of graphite electrodes is paramount, as they must endure repeated heating and cooling cycles. Factors such as the purity of the raw materials used in their production, the manufacturing process, and the specific properties of the graphite, including density and electrical resistivity, all influence the performance of these electrodes. High-quality graphite electrodes ensure consistent melting processes, reduce energy consumption, and improve the overall yield of the final steel products.

Furthermore, advancements in technology have led to the development of ultra-high power (UHP) graphite electrodes, which can handle even greater electrical currents and withstand higher temperatures. This innovation has made it possible to increase the production capacity of EAFs, allowing manufacturers to meet the growing demand for steel in various industries, including construction, automotive, and energy.

In addition to their practical applications, the use of graphite electrodes also raises considerations regarding sustainability. The steel industry is under continuous pressure to reduce its carbon footprint, and transitioning to more efficient methods, such as EAFs, aligns with these environmental goals. Graphite electrodes can be produced from recycled materials, further minimizing their environmental impact.

In conclusion, graphite electrodes are a fundamental element in modern steel-making processes, significantly affecting efficiency, quality, and sustainability. Understanding the role and properties of these electrodes helps industry professionals make informed decisions about sourcing and utilizing them in steel production. As the demand for innovative and sustainable metallurgical practices grows, the importance of high-quality graphite electrodes will undoubtedly continue to rise.

Previous:

Focus On Hot Spots

Understanding Graphite Electrodes for Steel Making: A Key Component in Metallurgical Processes

Graphite electrodes are essential components in the production of steel using Electric Arc Furnaces (EAFs). These electrodes serve as conductive materials that facilitate the passage of electric current, generating the temperatures necessary for melting scrap steel and other ferrous materials. The production of steel through this method has gained immense popularity due to its energy efficiency an

UHP Graphite Electrodes: Understanding Their Chemical Resistance and Applications

UHP Graphite Electrodes: Understanding Their Chemical Resistance

Table of Contents

Introduction to UHP Graphite Electrodes

Chemical Properties of UHP Graphite Electrodes

Advantages of UHP Graphite Electrodes

Applications of UHP Graphite Electrodes in Industry

Chemical Resistance of UHP Graphite Electrodes

Factors Affecting Chemical Resistance

Maintenance of UHP Graphit