Application of Graphite Electrode Joint

Application of Graphite Electrode Joint

1. Introduction

Graphite electrode joints have a wide range of applications in the electrical industry, and their unique physical and chemical properties make them an ideal choice in this field. This article will introduce the application of graphite electrode joints in detail to help you better understand its role and advantages in different scenarios.

Overview of 2. graphite electrode joints

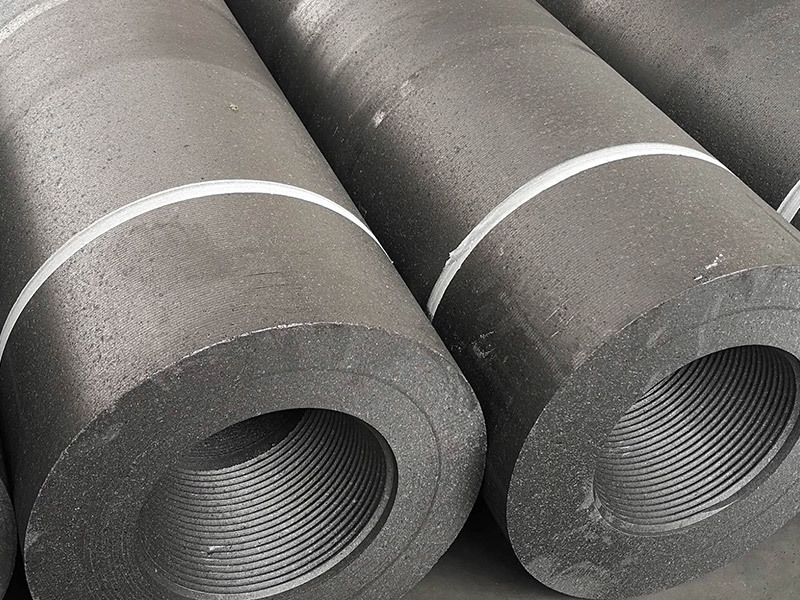

The graphite electrode joint is made of graphite material and is used to connect the power supply and the electrode parts. It has good electrical conductivity, high thermal conductivity, corrosion resistance and excellent mechanical strength, making graphite electrode joints have an irreplaceable position in the field of electrical industry.

Application fields of 3. graphite electrode joints

1. Electrolytic aluminum industry

Graphite electrode joints are widely used in the electrolytic aluminum industry, mainly used to connect the power supply and the anode to ensure the stable transmission of current. Its excellent conductivity and corrosion resistance make the graphite electrode joint can still maintain good performance in harsh working environment.

2. Electrolytic copper industry

In the electrolytic copper industry, graphite electrode joints also play an important role. Due to its high thermal conductivity and good electrical conductivity, graphite electrode joints can improve the efficiency of the electrolysis process, reduce energy consumption, and thus improve production efficiency.

3. Other non-ferrous metal smelting

Graphite electrode joints are also widely used in the smelting of other non-ferrous metals, such as zinc, nickel, lead and other metals. In these processes, the graphite electrode joint can ensure the stable transmission of current and improve the smelting efficiency.

Advantages of 4. graphite electrode joints

1. Excellent conductivity: The graphite electrode joint has extremely high conductivity, which can ensure the stable transmission of current, thereby improving the electrolysis efficiency.

2. High thermal conductivity: Graphite material has good thermal conductivity, which helps the rapid transfer and dissipation of heat, and ensures the temperature stability of the electrode joint.

3. Corrosion resistance: The graphite electrode joint can resist the erosion of various corrosive media, thereby prolonging the service life.

4. Reliable mechanical strength: The graphite electrode joint has high mechanical strength and can withstand greater pressure and tension to ensure the safety and reliability of the connection.

5. Easy to process and install: The process of processing and installing the graphite electrode joint is relatively simple, which reduces the production cost and installation cost.

5. practical application cases

Taking an electrolytic aluminum factory as an example, the graphite electrode connector is used to connect the power supply and the anode, which realizes the stable transmission of current. During use, the graphite electrode joint exhibits excellent conductivity and corrosion resistance, which greatly improves the electrolysis efficiency and reduces energy consumption. At the same time, the graphite electrode joint of the factory has good thermal conductivity, which ensures the temperature stability of the electrode joint, thereby improving the production efficiency.

6. Conclusion

In summary, graphite electrode joints have a wide range of applications in the field of electrical industry, especially in the electrolytic aluminum, electrolytic copper and other non-ferrous metal smelting process plays an important role. Its excellent electrical conductivity, high thermal conductivity, corrosion resistance, and reliable mechanical strength allow graphite electrode joints to perform well in these scenarios. In addition, the processing and installation process of the graphite electrode joint is relatively simple, which reduces the production cost and installation cost. Therefore, the graphite electrode joint has broad application prospects in the field of electrical industry.

The next one:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries