How to Identify Quality Graphite Crucibles for Your Workshop

Summary:

How to Identify Quality Graphite Crucibles for Your Workshop

Table of Contents

1. Understanding Graphite Crucibles

2. Importance of Quality Graphite Crucibles

3. Key Features of Quality Graphite Crucibles

3.1 Material Quality

3.2 Design and Shape

3.3 Thermal Resistance

3.4 Size and Capacity

4

How to Identify Quality Graphite Crucibles for Your Workshop

Table of Contents

- 1. Understanding Graphite Crucibles

- 2. Importance of Quality Graphite Crucibles

- 3. Key Features of Quality Graphite Crucibles

- 4. Identifying Quality Graphite Crucibles

- 5. Choosing the Right Supplier

- 6. Maintenance and Care for Graphite Crucibles

- 7. Frequently Asked Questions

- 8. Conclusion

1. Understanding Graphite Crucibles

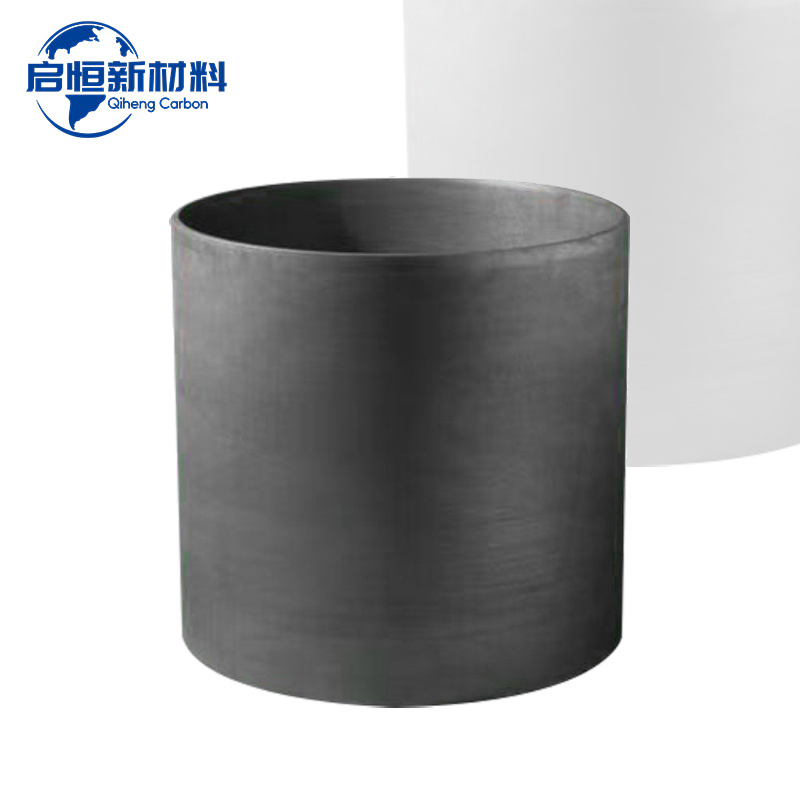

Graphite crucibles are specialized containers designed for high-temperature melting and casting processes. The unique properties of graphite, such as its high thermal conductivity, resistance to thermal shock, and excellent chemical stability, make it an ideal material for crucibles. These crucibles are widely used in various industries, including metallurgy, casting, and laboratory applications, where precision and durability are paramount.

2. Importance of Quality Graphite Crucibles

The quality of your graphite crucibles directly impacts the efficiency and effectiveness of your workshop operations. High-quality crucibles provide better heat retention, reduce melting times, and improve the overall results of your casting projects. Investing in reliable crucibles not only enhances performance but also minimizes the risk of contamination and product failure, ensuring that your work meets the highest standards.

3. Key Features of Quality Graphite Crucibles

When selecting graphite crucibles, several essential features should be considered to ensure you're making the right choice. Below are the key attributes that distinguish quality crucibles from lesser options.

3.1 Material Quality

The material used in the crucible's construction is crucial. Quality graphite crucibles are made from high-purity graphite, which offers superior thermal properties and durability. Look for crucibles that are free from impurities and voids, as these can weaken the structure and lead to premature failure.

3.2 Design and Shape

The design of the crucible plays a significant role in its performance. A well-designed crucible facilitates even heat distribution and minimizes hot spots, enhancing melting efficiency. Common shapes include cylindrical and conical forms, each suited for specific applications. Ensure the design matches your melting requirements for optimal results.

3.3 Thermal Resistance

Quality graphite crucibles exhibit excellent thermal resistance, allowing them to withstand extreme temperatures without cracking or deforming. Look for crucibles rated for high temperatures, typically above 1600°C (2912°F), to ensure they can handle your specific melting processes.

3.4 Size and Capacity

Choosing the right size and capacity is essential for achieving effective melting and casting. Consider the volume of material you plan to melt and select a crucible that accommodates this requirement without being excessively large, which could waste energy and resources.

4. Identifying Quality Graphite Crucibles

It is vital to know how to identify quality graphite crucibles to make informed purchasing decisions. Here are two effective methods.

4.1 Visual Inspection

Performing a visual inspection is an excellent first step in determining the quality of graphite crucibles. Look for smooth finishes, uniform color, and a consistent texture. Any cracks, chips, or irregularities may indicate poor manufacturing quality.

4.2 Testing Performance

If possible, conduct a performance test before making a purchase. This involves heating the crucible to its specified temperature and monitoring its performance. A quality crucible should retain its shape and integrity throughout the process without any signs of deformation or cracking.

5. Choosing the Right Supplier

Selecting a reputable supplier is critical for obtaining quality graphite crucibles. Look for manufacturers with a proven track record, positive customer reviews, and certifications that verify their production standards. A reliable supplier should also provide clear information about the crucibles, including specifications, material sources, and warranty options.

6. Maintenance and Care for Graphite Crucibles

Proper maintenance can significantly extend the life of your graphite crucibles. Here are some essential care tips:

1. **Cleaning**: After each use, clean the crucible thoroughly to remove any residual materials and contaminants. Avoid using abrasive cleaners, as they can damage the crucible's surface. Instead, use a soft brush or cloth.

2. **Storage**: Store crucibles in a cool, dry place, away from direct sunlight and extreme temperature changes. Protect them from physical damage by placing them in padded containers.

3. **Handling**: Always handle crucibles with care to prevent drops or impacts that could cause cracks or chips.

By following these maintenance tips, you can enhance the longevity and performance of your graphite crucibles.

7. Frequently Asked Questions

What materials can be melted in graphite crucibles?

Graphite crucibles are suitable for melting various metals, including gold, silver, aluminum, copper, and brass. Their high thermal stability makes them versatile for different alloys and casting applications.

How long do graphite crucibles typically last?

The lifespan of a graphite crucible depends on several factors, including the quality of the crucible, the materials being melted, and the operating temperatures. High-quality crucibles can last for several dozen melts if properly maintained.

Can I use graphite crucibles for induction melting?

Yes, graphite crucibles are compatible with induction melting processes. However, ensure you select a crucible specifically designed for induction melting, as they may feature reinforced structures.

Are there different grades of graphite crucibles?

Yes, graphite crucibles come in various grades, each suited for different applications. Higher-grade crucibles usually offer better thermal conductivity and durability, making them ideal for high-performance uses.

What should I do if my graphite crucible cracks?

If your graphite crucible cracks during use, it is best to discontinue its use immediately to avoid contamination and product failure. Depending on the severity of the crack, it may be possible to repair it temporarily, but replacing the crucible is generally recommended for consistent performance.

8. Conclusion

Choosing quality graphite crucibles for your workshop is essential for achieving optimal results in melting and casting applications. By understanding the critical features that define quality crucibles, engaging in thorough inspections, and selecting reputable suppliers, you can ensure that your workshop operates at its best. Proper maintenance further enhances crucible longevity and performance, allowing you to focus on your craft without the worry of equipment failure. With the insights provided in this guide, you are now equipped to make informed decisions and elevate the quality of your workshop operations.

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property