Graphite Electrode Connector: A Comprehensive Guide to Its Features and Benefits

Summary:

Graphite Electrode Connector: A Comprehensive Guide to Its Features and Benefits

Table of Contents

1. Introduction to Graphite Electrode Connectors

2. What Are Graphite Electrode Connectors?

3. Key Features of Graphite Electrode Connectors

4. Benefits of Using Graphite Electrode Connectors

5. Applications of Graphite Electrode Connectors

6. Types of Graphite Electrode Conn

Graphite Electrode Connector: A Comprehensive Guide to Its Features and Benefits

Table of Contents

- 1. Introduction to Graphite Electrode Connectors

- 2. What Are Graphite Electrode Connectors?

- 3. Key Features of Graphite Electrode Connectors

- 4. Benefits of Using Graphite Electrode Connectors

- 5. Applications of Graphite Electrode Connectors

- 6. Types of Graphite Electrode Connectors

- 7. Installation and Maintenance

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Graphite Electrode Connectors

Graphite electrode connectors are vital components used in various electrical applications. These connectors ensure efficient and reliable electrical connectivity in environments that require stable performance under high temperatures and electrical stress. As industries evolve and demand increases for efficient energy systems, understanding the characteristics and advantages of graphite electrode connectors becomes essential.

2. What Are Graphite Electrode Connectors?

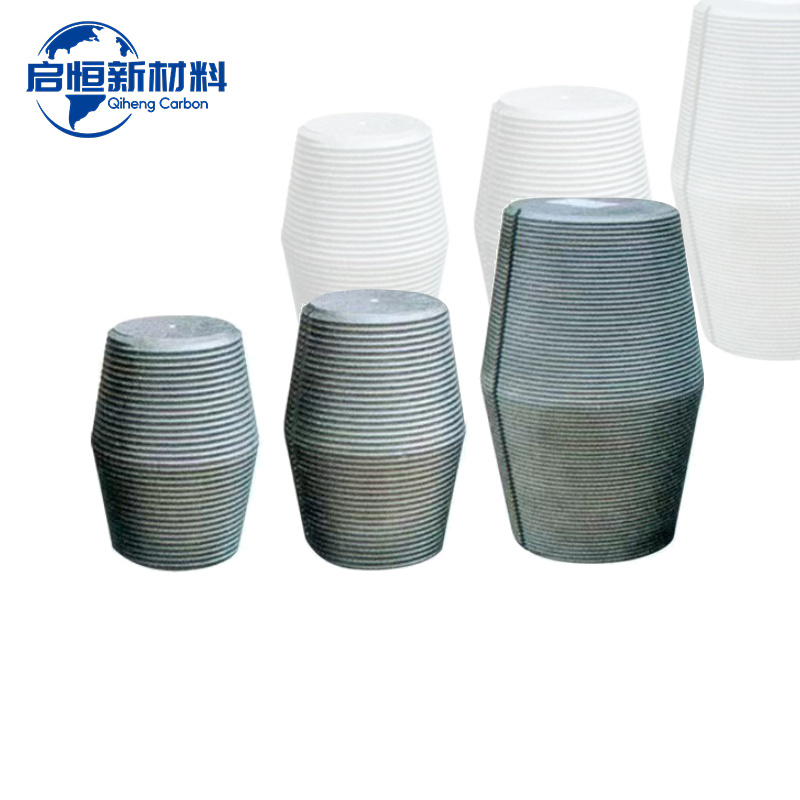

Graphite electrode connectors are specialized fittings that facilitate the connection of graphite electrodes in electric arc furnaces and other high-temperature applications. Made primarily from high-quality graphite, these connectors can withstand extreme conditions, including high temperatures and electrical currents. Their design allows for efficient power transfer and minimal resistance, making them indispensable in many industrial settings.

Understanding Graphite

Graphite is a form of carbon known for its excellent conductivity and heat resistance. The properties of graphite make it an ideal choice for electrical connections, particularly in environments where temperature fluctuations and electrical surges are common.

3. Key Features of Graphite Electrode Connectors

Graphite electrode connectors possess several features that enhance their performance:

High Conductivity

One of the most significant benefits of graphite is its high electrical conductivity. This enables efficient power transfer, which is crucial for maintaining operational efficiency in industrial applications.

Temperature Resistance

Graphite connectors can withstand high temperatures, making them ideal for electric arc furnaces where temperatures can exceed 3000 degrees Fahrenheit.

Corrosion Resistance

The chemical stability of graphite means that these connectors are resistant to various corrosive substances, ensuring longevity and reducing maintenance costs.

Lightweight Design

Graphite electrode connectors are relatively lightweight compared to metal connectors, which simplifies handling and installation processes.

4. Benefits of Using Graphite Electrode Connectors

Utilizing graphite electrode connectors offers numerous benefits, including:

Enhanced Performance

With their ability to conduct electricity efficiently and withstand extreme conditions, graphite connectors help improve overall system performance, ensuring operational reliability.

Cost-Effectiveness

Although the initial investment might be higher than traditional connectors, the durability and reduced maintenance needs of graphite connectors can lead to lower long-term costs.

Improved Safety

The resistance to overheating and failure under stress enhances the safety of operations, reducing the risk of accidents in industrial settings.

Versatility

Graphite electrode connectors are applicable in various industries, including steelmaking, aluminum production, and electrical generation, making them a versatile choice for engineers and technicians.

5. Applications of Graphite Electrode Connectors

Graphite electrode connectors find applications across multiple industries:

Steel Manufacturing

In steel production, these connectors are essential components in electric arc furnaces, where they connect electrodes that melt scrap metal to produce molten steel.

Aluminum Production

Graphite connectors are also extensively used in aluminum smelting processes, where they ensure efficient electrical connections in high-temperature environments.

Power Generation

In power generation facilities, graphite electrode connectors play a crucial role in connecting electrodes within electrolysis cells, enhancing overall efficiency.

Research and Development

In laboratories and research facilities, these connectors are utilized in experimental setups that require precise electrical connections under controlled conditions.

6. Types of Graphite Electrode Connectors

There are several types of graphite electrode connectors to consider:

Standard Connectors

These are the most common type used in various applications, designed for general use in electric arc furnaces.

Custom Connectors

Some applications require specialized connectors tailored to specific operational needs. Custom designs can optimize performance in unique conditions.

High-Performance Connectors

For industries that demand maximum efficiency and reliability, high-performance connectors made with advanced materials and techniques are available, ensuring optimal performance.

7. Installation and Maintenance

Proper installation and maintenance of graphite electrode connectors are crucial for ensuring their longevity and effectiveness.

Installation Guidelines

1. **Preparation**: Ensure that all surfaces are clean and free of debris before installation.

2. **Alignment**: Align the electrodes and connectors accurately to avoid undue stress.

3. **Tightening**: Use proper torque specifications when tightening connectors to prevent damage.

4. **Testing**: Conduct electrical tests post-installation to verify performance.

Maintenance Tips

1. **Regular Inspections**: Check connectors for wear and tear regularly.

2. **Cleaning**: Keep connectors clean from contaminants that may impair conductivity.

3. **Temperature Monitoring**: Monitor operating temperatures to prevent overheating.

8. Frequently Asked Questions

What are the primary materials used in graphite electrode connectors?

Graphite electrode connectors are primarily made from high-quality graphite, which provides excellent conductivity and heat resistance.

How do graphite electrode connectors compare to metal connectors?

Graphite connectors offer higher conductivity, better temperature resistance, and lower weight compared to traditional metal connectors.

What industries benefit most from graphite electrode connectors?

Industries such as steel manufacturing, aluminum production, and power generation significantly benefit from the use of graphite electrode connectors.

Are graphite electrode connectors customizable?

Yes, many manufacturers offer custom designs of graphite electrode connectors to suit specific application needs.

How do I maintain graphite electrode connectors?

Regular inspections, cleaning, and temperature monitoring are essential for maintaining graphite electrode connectors' effectiveness and longevity.

9. Conclusion

Graphite electrode connectors are indispensable components in modern industrial applications, providing reliable, efficient, and safe electrical connections in high-temperature environments. Their unique properties, such as high conductivity and thermal resistance, make them a superior choice over traditional connectors. By understanding the features, benefits, and applications of graphite electrode connectors, industries can optimize their electrical systems and enhance operational efficiency. For engineers and technicians seeking to improve their systems, investing in high-quality graphite electrode connectors is a decision that promises long-term benefits and reliability.

Previous:

Focus On Hot Spots

RP Graphite Electrodes: Transforming Conductivity in Metallurgical Processes

RP Graphite Electrodes: Enhancing Conductivity in Metallurgical Applications

Table of Contents

1. Introduction to RP Graphite Electrodes

2. Understanding Graphite and Its Properties

3. The Role of RP Graphite Electrodes in Metallurgy

4. Benefits of Using RP Graphite Electrodes

5. The Manufacturing Process of RP Graphite Electrodes

6. Applications of RP Graphite Electrodes

The Essential Guide to Graphite Blocks in Metallurgy and Energy Industries

Graphite blocks are pivotal materials in the metallurgy and energy industries, particularly within the non-metallic mineral products sector. These blocks, made from natural or synthetic graphite, possess unique properties that make them suitable for a wide range of applications. One of the most notable characteristics of graphite is its excellent thermal and electrical conductivity. This property